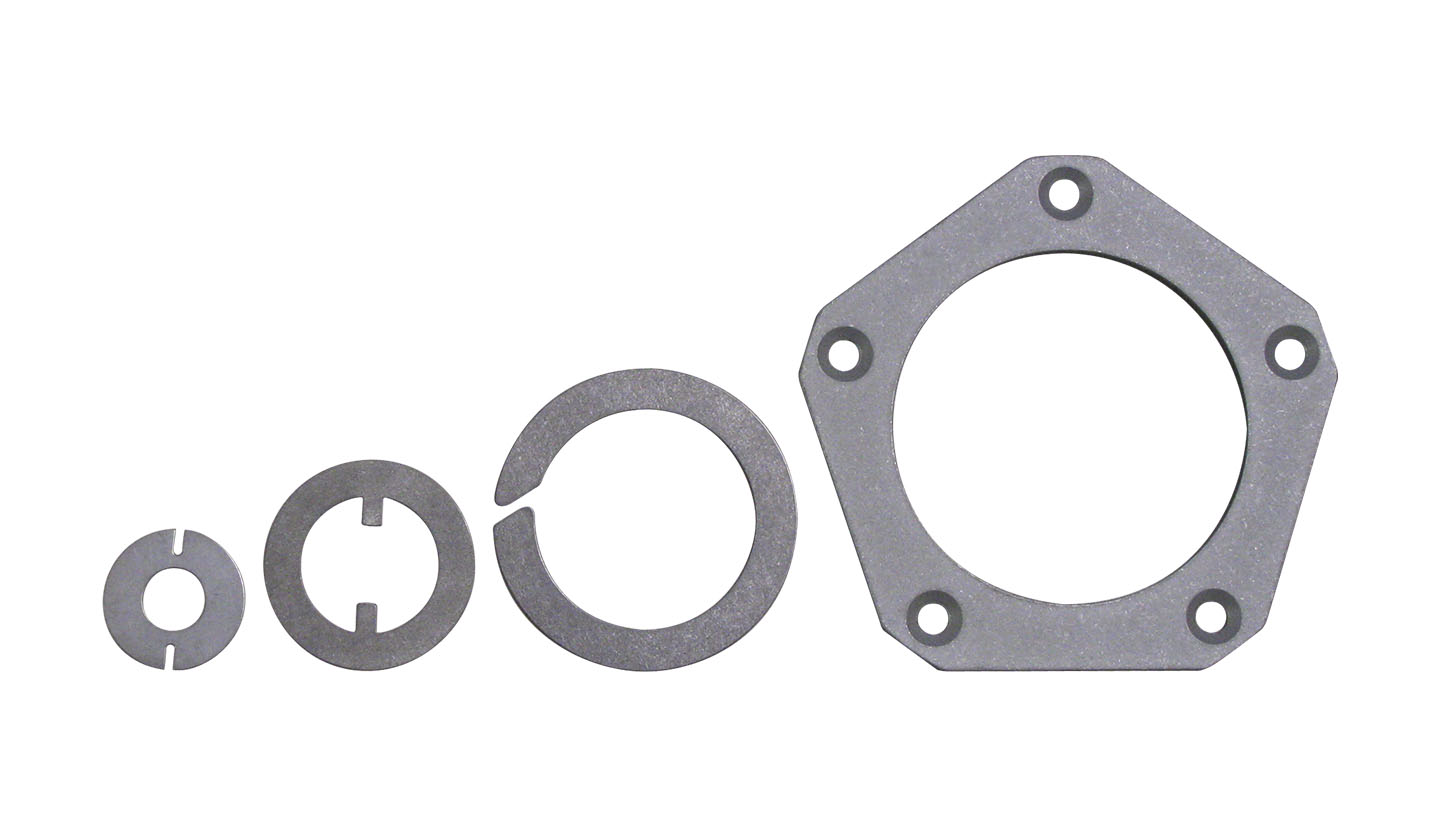

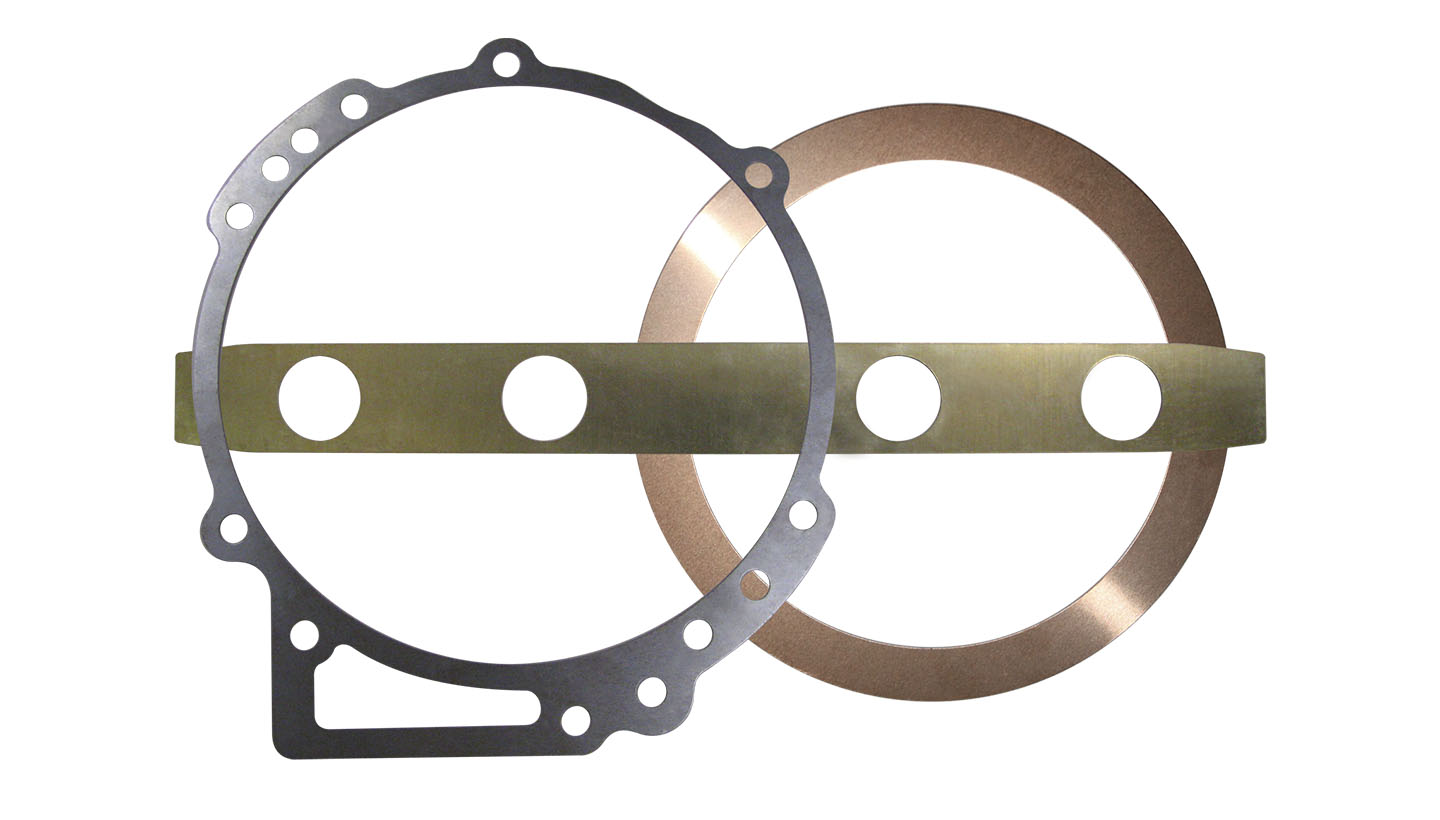

SPIROL is a manufacturer of custom Precision Shims with or without a tool to meet lead-time and total cost considerations. Shims are thin pieces of metal material often used as compensators to fill in small gaps between objects aligning parts, reducing wear and absorbing tolerances between mating components. Precision Shims can also significantly reduce manufacturing time and costs as they eliminate the need for each component to be machined in order to achieve the proper fit and function of the total assembly.

SPIROL produces Shims custom-made to customer specifications in thicknesses from 0.02mm up to 9.5mm (.001″ up to .375″) from a comprehensive inventory of raw materials including but not limited to:

Each material offers specific benefits for our customers’ specific applications including corrosion resistance, wear resistance and more, making them ideal in many industries. To further accommodate certain industries and applications, there are a number of finishing options available for our Shims designed to protect against particular environmental conditions, such as exposure to salts and corrosives, humidity and galvanic corrosion.

We specialize in complicated parts in small quantities; yet are fully equipped to manufacture low, medium and high volumes.

Most secondary processes are performed entirely in-house affording complete control over lead-time and quality. Many secondary bundling and packaging options are available to facilitate ease of assembly considerations.

Read How to Control Shim Tooling Costs and other White Papers from SPIROL.

Contact us for complimentary technical assistance for your Shim application.