Pin Installation Technology

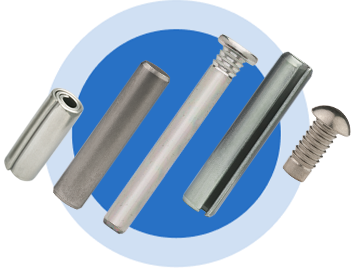

SPIROL Pin Inserters feed all common types of pins — headed or straight — as well as Bushings, Rivets, Press-In Inserts and many other similar components.

Whether your requirements are for a standard Pin Inserter (with or without fixturing) or a custom designed system, our objective is to build reliable and cost effective equipment that provides the right degree of automation based on the volume and complexity of the assembly process involved; the degree of automation that yields the lowest per unit assembly cost and the optimum pay back.

We offer:

- Pin Driving Chucks

- Manual, semi-automatic, and automatic machines

- Simultaneous multiple insertions

- Vertical and horizontal styles

Optional enhancements for enhanced productivity, heightened process control and error-proofing include:

- Rotary index tables

- Pin sensing

- Force monitoring

- Drilling and pinning combinations

- Laser part presence

- Pin level monitoring in the feed tube and bowl

Standard Pin Inserter types include:

Manual Pin Inserters and Pin Driving Chucks provide sturdy, economical installation methods for low-volume work and prototype designs. Manual Pin Inserters require that the fastener be manually loaded into the part or the machine. The operator then completes the installation by depressing the arbor press lever.

Automatic Pin Inserters are completely self-contained. The fastener is oriented in a vibratory feeder and fed to a shuttle mechanism that positions the fastener directly underneath the insertion quill. The shuttle is mounted on a retracting mechanism that positions the shuttle as close to the part as possible for insertion, yet out of the way for loading and unloading.

Vertical Pin Inserters are available in a wide range of sizes matched to pin lengths and insertion force requirements. Standard machines capable of simultaneous multiple insertions are available.

Horizontal Pin Inserters for single or multiple installations feature rotary shuttles for reliable pin orientation.

Pin Installation Product Listing

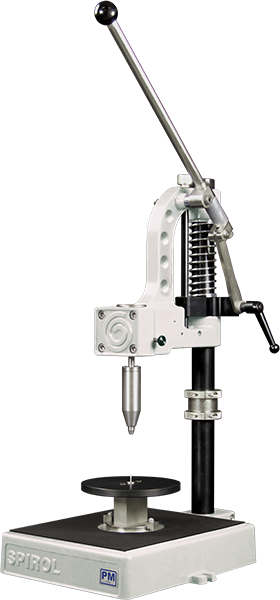

Model PM Manual Pin Inserter

This exceptionally versatile tool is ideally suited to all levels of production: from a single unit for prototype assembly, to multiple units on an assembly line. The Model PM Manual Pin Inserter easily accommodates quick change-overs. The part holding device (fixture) is simply replaced from the base of the machine. The pin diameter is easily changed, positive pin depth easily adjusted, and part size variation easily accommodated. The use of high-tech shafting and bearings results in smooth operation, precise positioning, repeatability, and durability.

The Model PM Manual Pin Inserter installs pins ranging in diameter from 0.8mm-4mm (.031”-.156”) with a maximum insertion force of 0.9 kN (200 lbs).

Model PMH Heavy Duty Manual Pin Inserter

The precisely machined rack and casting results in smooth operation, precise positioning, repeatability, and durability.

The Model PMH Heavy Duty Manual Pin Inserter installs pins ranging in diameter from 0.8mm-10mm (.031”-.375”) with a maximum insertion force of 6.7 kN (1,500 lbs).

Model PMX Extra Heavy Duty Manual Pin Inserter

This versatile tool is ideally suited for low to moderate levels of production for assemblies that require installation forces up to 22.2 kN (5,000 lbs). The Model PMX Extra Heavy Manual Pin Inserter easily accommodates quick change-overs. The fixture is simply replaced at the base of the machine, and the pin diameter is easily changed by switching the pin driving chuck. This Extra Heavy Duty Manual Pin Inserter will provide smooth operation, repeatability and durability.

Pin Driving Chucks

SPIROL offers a line of light duty and heavy duty Pin Driving Chucks designed to be used in SPIROL’s Manual Pin Inserters (Model PM, Model PMH or Model PMX). A Pin Driving Chuck may also be used in a drill press or arbor press with an adaptor. All Pin Driving Chucks are designed with spring tension at the tip to hold the pin securely in place prior to and during installation. The exposed end of the pin is then placed into the hole and the tool is advanced to complete the installation. The tools are supplied with a flush, above-flush or below-flush setting, depending on the application requirements.

Model PR Semi-Automatic Pin Inserter

This versatile installation machine is suited for moderate to high production applications requiring up to 1.3 kN (300 lbs.) of installation force. The pin insertion head advances and retracts for ease of loading and unloading of the components to be pinned. The machine’s insertion bushing is positioned close to the part for smooth installation.

A vibratory feeder and orientation head transfers the pin from the feeder bowl to the installation position, eliminating the need for the operator to handle the pins. A quick-clear mechanism allows for easy clearing of the feed tube without the need for tools when changing pin size or performing maintenance.

Model CR Semi-Automatic Heavy Duty Pin Inserter

SPIROL's Model CR Semi-Automatic Heavy Duty Pin Inserter is a robust, vertical pin insertion machine ideally suited for moderate to high production for applications requiring up to 8kN (1,800 lbs) of installation force. A retractable pin orientation head, mounted on a shaft/linear bearing arrangement moves up and down for ease of loading and unloading of the components to be assembled. The insertion bushing is positioned close to the part for smooth, trouble free installation.

The orientation head shuttles the pin from the feeding position to the installation position, and also functions as a selector, preventing longer or shorter pins from being installed. A two position trap door allows for easy clear-out of the feed tube.

Model HC Horizontal Dual Pin Inserter

SPIROL's Model HC Dual Pin Inserter is a lightweight, portable, horizontal Pin Inserter designed to install SPIROL Series 550 Cosmetic Coiled Pins into plastic hinges. The cylinder/driving head modules can be moved in and out with ease, and fixture changes are simple which enables quick conversion from one assembly to another. This machine quickly and effectively delivers the pins automatically to the installation site eliminating the need for the operator to touch them during the entire assembly operation. This machine dramatically increases production efficiency with minimal operator training and effort.

Model DP Drilling & Pinning Machine

SPIROL's Model DP self-contained vertical drilling and pinning machine is ideally suited for moderate to high production applications that require accurate drilling and pinning of assemblies. The concept of drilling and pinning with one system eliminates tight tolerance and precision drilling of individual components to ensure proper alignment of holes for assembly. The Model DP Drilling and Pinning Machine consists of an automatic high-precision drilling unit, a SPIROL Model CR Heavy Duty Pin Insertion Machine and a precision air-powered linear slide unit to move the assembly between the drill unit and installation station.

The Model DP Drilling and Pinning Machine can drill holes ranging in diameter from 0.8mm-6mm (.031”-.250”) and is capable of insertion forces up to 8 kN (1,800 lbs).

Additional Fastener Installation Technology and Equipment

Customizable Solutions

SPIROL Application Engineers are available to review your application requirements, and make critical recommendations for the Pin and installation method for the best quality and overall lowest total installed cost assembly. We are here to help!

Installation Technology for Pins

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Pin Installation Equipment designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automatic work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+86 021-5046 1451

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국