Pre-Assembled Disc Spring Stacks

SPIROL offers Disc Springs pre-stacked in custom configurations (greased or ungreased) packaged in shrink wrap with a perforated tab for ease of insertion into the assembly. The Pre-Assembled Disc Springs are delivered intact which saves time, mistake-proofs the assembly process, and eliminates the mess associated with greasing the stack.

Have an existing Disc Spring Stack Application? If you have an existing Disc Spring Stack that you would like quoted, please Request a Quote. We are here to help!

Application Engineering Support: SPIROL Engineering will assist in determining the optimum Disc Spring Stack configuration to meet your specific application requirements. To engage SPIROL’s technical team, simply Request Engineering Support or Contact Us at our closest global location.

Disc Spring Product Listing

Pre-Assembled Disc Springs

For existing applications, please Request a Quote and provide SPIROL with the drawing of your custom Disc Spring Stack assembly along with your quantity, delivery and any other requirements, and one of our team members will respond quickly to you. If you would like assistance in determining the most appropriate Disc Spring Stack for your application, please Request Engineering Support. We are here to help!

Additional Disc Spring Options

Need Help?

SPIROL’s Application Engineers will assist you in the design and selection of the most cost effective Disc Spring Stack to fit in your space constraints while meeting your specific force and deflection requirements. Our experienced team can often configure a stack of smaller, less costly Disc Springs to get the same performance as larger, more expensive Discs. Our Engineers will also assist in developing special Disc Spring Stacks to meet the requirements of unique applications. This includes special dimensions, materials, finishes, shapes, shot peening, presetting and stacking.

Simple Drop-in Assembly

Delivered fully assembled to streamline installation and reduce assembly time.

Customized Packaging: Tailored packaging solutions developed in collaboration with you to ensure secure transport and ease of handling.

Part Marking Options:

- Directional indicators to ensure correct orientation during installation.

- Visual cues on the Disc Spring Stack for clear, at-a-glance confirmation of proper configuration within the assembly.

Pre-Checked Quality Assurance: Every Disc Stack undergoes a quality check to verify correct orientation and custom part-marketing & packaging requirements before shipping.

Fully Customizable Packaging and Part Marking

Custom options include:

- Various packaging types

- Lubrication choices

- Part markings

- The flexibility to accommodate special requirements

Specifications

SPIROL manufactures Pre-Assembled Disc Spring Stacks using Disc Springs produced to DIN 16983 standards. These range in size from miniature 8mm outer diameters—ideal for compact or precision mechanisms—to large 200mm diameters, comparable in size to standard industrial flanges or pressure gauge housings.

Between these extremes, we offer a full range of sizes suitable for applications from precision instruments and automotive components to heavy-duty industrial equipment.

Application Success Stories

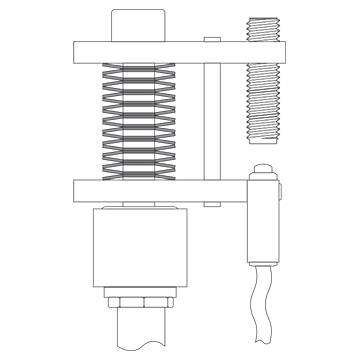

Disc Spring Stack in Crane Overload Safety Switch

Customer Challenge:

A manufacturer approached SPIROL for assistance on designing a stack of Disc Springs that would reliably activate an overload mechanism for a warehouse crane. The manufacturer’s design allowed the crane to function within a range 800 – 2400kg (7.85 – 23.54kN), and the Disc Springs were to activate the overload mechanism preventing the use of the crane at loads over 2700kg (26.48kN). The manufacturer’s design parameters limited the maximum Disc Spring diameter to 94mm and a stack height of 150mm.

Although the stop mechanism is only used on the rare occasion when the crane is overloaded, this is considered a dynamic application as the Disc Springs will be cycling each time the crane is used.

SPIROL SOLUTION:

- SPIROL’s Application Engineering Team determined that (20) alloy steel (51CrV4) Disc Springs (DSC 90 x 46 x 5mm WR) stacked in series would provide the nominal force/deflection requirements within the physical constraints of the design. To ensure the Disc Spring Stack would perform as desired at the minimum and maximum material conditions, SPIROL Engineering’s evaluation included calculating the performance of the Disc Spring Stack at the extreme limits of the tolerance range. This included the spring force tolerance of the Disc Spring (+10 / -5% @s = 0.75ho) coupled with ± 2-3% applied to the final force value to account for the minimal effect of friction between the Disc Springs since there were no Discs stacked in parallel.

- In the end, the recommended Disc Spring Stack met all performance requirements within the physical constraints of the design.

- For more information, read our White Paper “How to Determine the Proper Disc Spring Stack Configuration”

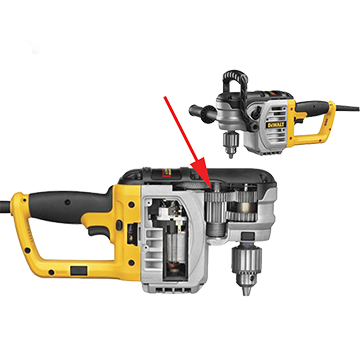

Disc Spring Stack in Mechanical Clutch in Heavy Duty Right Angle Drill

Customer Challenge:

The lead engineer at a prominent hand and power tool company contacted SPIROL for help determining the best Disc Spring design for a new lightweight, compact, and portable Heavy Duty Right Angle Drill.

SPIROL SOLUTION:

- SPIROL Engineering designed two special Disc Springs stacked in series to meet the specific force and deflection requirements.

- Disc Springs offer a higher load capacity in less space as compared to conventional coil springs which enables the designer to make the tool more compact.

- Unlike Belleville Washers that are mostly used in static applications, Disc Springs provide unparalleled predictability, reliability and fatigue life in highly dynamic applications.

- By partnering with SPIROL and incorporating our recommendation, the customer minimized costly development time and confidently launched their new high-quality drill to the market.

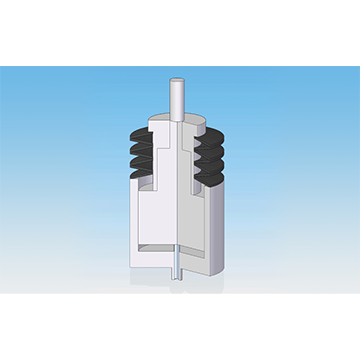

Disc Spring Stack in Turret Punch Press Assembly

Customer Challenge:

Traditional turret punch press tool designs utilize coil springs (die springs) to facilitate the stripping mechanism of a die. Rather than using a ram to push the punch through the sheet metal and pull it out, the spring automatically retracts the punch. This allows the ram to only have to work in one direction. The result reduces wear and extends the cycle life of the press.

SPIROL SOLUTION:

- Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process.

- SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series (Figure 1), they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+86 021-5046 1451

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España