Application Specific Solid Pins

SPIROL designs and manufactures specific types of Solid Pins to meet the performance and assembly requirements of common niche applications. These Solid Pins are variations of our standard product either manufactured from specific material, have a specific finish or undergo specific processing to meet performance, corrosion, compatibility and assembly requirements for the specific application. These pre-designed application-specific series of Solid Pins help companies shorten the design cycle to confidently launch their product quickly to the market with a pinning solution that has been tested and proven within their assembly.

Check out SPIROL’s application-specific Solid Pins below.

Application Engineering Assistance: If you would like assistance in selecting the proper Solid Pin for your assembly, please Request Engineering Support! We are here to help!

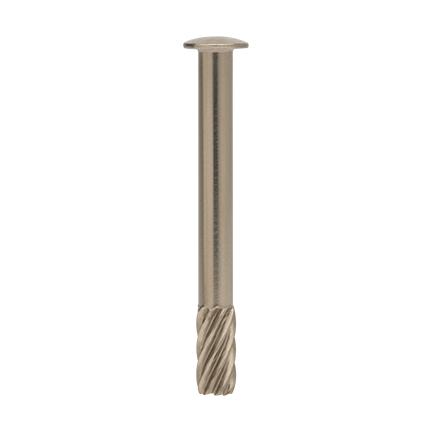

Latch Pins for Plastics

SPIROL's Series LP500 Latch Pins for Plastics are designed with a barb located under the head with a barb length equal to the width of the outermost section of the assembly. The remaining length of the LP500 Latch Pin is smooth without any other retention features. This allows the LP500 Latch Pin for Plastic to easily align and freely install through all of the holes with a plastic assembly until the barb makes contact with the final hole to securely lock the pin in place. Once fully installed, the handle will pivot freely around the non-barbed end of the stationary pin. The head prevents the LP500 Latch Pin from being over-installed, and enables the pin to be mechanically oriented for automatic installation. Manufactured from lightweight, lead free aluminum, SPIROL's LP500 Latch Pins for Plastics are available in three standard diameters: 3mm, 4mm and 5mm.

Twist-Lok™ Pins

Series RH600 Twist-Lok™ Pins replace costly screw machined pins and eliminate problematic installation of screws and rivets. The helical knurl minimizes stress during installation by rotating as it engages the hinge. Corrosion-resistant material and a rounded burr-free head improve installed appearance. Axial and radial forces induced in the hinge eliminate the tendency for the pin to creep and maintain hinge tension.

Additional Solid Pin Types

Customizable Solutions

If you are unable to find the Solid Pin in the diameter, length, material, or finish that you require within our standard offering, or if you are unsure what type of pin is most appropriate for your assembly, Request Engineering Support from our team and we will help you select the most cost-effective solution for your application.

Installation Technology for Pins

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Pin Installation Equipment designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automatic work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Application Success Stories

Hinge Pin in Automotive Interior Door Handle Latch Mechanism

Customer Challenge:

An automotive door handle manufacturer approached SPIROL to recommend a hinge pin that would eliminate the BSR (buzz, squeak & rattle) caused by a semi-tubular rivet they were using in their assembly.

SPIROL SOLUTION:

- SPIROL’s LP500 Latch Pin for Plastics was specifically developed for the automotive handle and latch market.

- The barbed section under the head of the LP500 Latch Pin for Plastics locks the pin into the plastic host assuring the handle pivots properly while the pin remains stationary. This also completely eliminates the concern for BSR.

- Since the pin is pressed securely into place upon insertion, all secondary operations such as riveting and peening are eliminated.

- Replacing the current Semi-Tubular Rivet with SPIROL’s LP500 Latch Pin for Plastics simplified the assembly process, improved production efficiencies, eliminated lubricants, and improved the overall product quality of the door handle.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+86 021-5046 1451

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España