Light Duty Coiled Spring Pins

SPIROL invented the Coiled Spring Pin in 1948. Truly an engineered fasteners, the Coiled Pin is available in three duties, light, standard and heavy, to enable the designer to choose from the optimum combination of strength, flexibility and diameter to suit different host materials and application requirements. Their shock absorbing design dampens forces and vibration to prevent hole damage and prolong assembly life.

Light Duty Coiled Spring Pins are generally recommended for soft, brittle or thin materials such as plastics, aluminum, die castings, ceramics, and where holes are located close to an edge of the assembly. In situations not subjected to significant loads, such as when used purely for alignment or as an axle, light duty Coiled Pins are often used because of easy installation resulting from lower insertion force.

Application Engineering Assistance: If you would like assistance in selecting the proper diameter and duty Coiled Spring Pin for your assembly, please Request Technical Support! We are here to help!

Shop Our Light Duty Coiled Pins: For small quantities, click the Shop Now button below. For larger quantities or custom requests, please Request a Quote and one of our team members will get back to you quickly!

Metric Sizes - Light Duty

SPIROL's light duty metric Coiled Spring Pins conform to ISO 8751 and ASME B18.8.3M and range in diameter from 1.5mm up to 8mm. Light duty Coiled Pins are offered in high carbon steel, 302/304 nickel (austenitic) stainless steel and 420 chrome (martensitic) stainless steel.

Inch Sizes - Light Duty

SPIROL offers inch (imperial) light duty Coiled Spring Pins in diameters ranging from .062" (1/16) up to .312" (5/16). Standard materials include high carbon steel, 302/304 austenitic (nickel) stainless steel, and 420 martensitic (chrome) stainless steel. Light duty inch Coiled Pins conform to ASME B18.8.2.

Additional Coiled Spring Pin Types

Customizable Solutions

If you are unable to find the light duty Coiled Spring Pin in the diameter, length, material, or finish that you require within our standard offering, or if you are unsure what Coiled Pin is most appropriate for your assembly, Request Technical Support from our team and we will help you find the most cost-effective solution for your application.

Installation Technology for Pins

In addition to a comprehensive line of engineered components used for joining and assembly, SPIROL also offers a full range of Pin Installation Equipment designed to facilitate cost-effective and high quality assembly of your products. Our installation solutions range from manual machines to fully automatic work cells with statistical process control and error-proofing options. We are the only company of our kind that offers the total integrated solution.

Application Success Stories

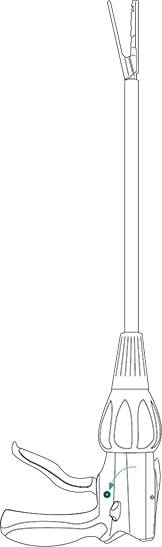

Trigger Pin in Surgical Stapler

Customer Challenge:

A leading medical device manufacturer approached SPIROL for assistance in designing a self-retaining trigger pin that eliminated cracking of the plastic yoke within the surgical stapler.

SPIROL SOLUTION:

- SPIROL Engineers recommended a Light Duty Coiled Spring Pin which was designed specifically for plastic assemblies to ensure the perfect balance of strength and flexibility.

- Coiled Pins are easy to install and exert low stress on the hole after installation, yet they provide exceptional retention.

- In addition to recommending the most appropriate pin, SPIROL Engineers also recommended the hole sizes for each of the retaining locations to make sure that the assembly functioned properly over the life of the assembly.

- SPIROL’s Coiled Spring Pin eliminated the cracking of the plastic yoke, enhanced the function of the trigger, and improved the overall quality of the surgical stapler.

Hinge Pin in Plastic Protective Storage Case

Customer Challenge:

A plastic storage case had been designed with a latch/hinge assembly requiring two pins. One pin was used to connect the entire latch assembly to the case lid, and the other pin was used as a hinge pin within the latch assembly.

The original pins that were used were solid pins that had a barb on one end. Due to its asymmetrical design these pins could not be easily oriented for use in automated feed equipment. In addition, the solid pin could not provide a reliable friction fit hinge so a feature had to be designed into the case to create interference. The manufacturer decided to replace the current pins with one that was better suited for use in automated equipment and capable of providing a quality friction fit hinge without the need of additional features built into the case.

SPIROL SOLUTION:

SPIROL Engineering recommended a light duty Coiled Pin for use in this assembly. Light duty pins offer superior flexibility, which eases installation and protects hole integrity in plastic components. This results in reliable retention and a consistent “feel” of the hinge throughout the life of the product. A single pin could be used in both locations, and SPIROL Engineering provided the hole sizes necessary to achieve the desired “fits.” A 300 series austenitic stainless steel pin was selected as it provided excellent corrosion resistance in the environments in which the case would be used. This cost effective solution satisfied all of the application requirements and could quickly be manufactured to meet demand.

Hinge Pin in Automotive Door Handle

Customer Challenge:

The customer was using a staked tubular rivet as a hinge pin for the handle and pawl in an automotive door handle application. The customer was experiencing problems with BSR (buzz, squeak and rattle) with the tubular rivet. They tried staking the rivet tighter to the assembly, however this caused cracking of the plastic boss. The customer approached SPIROL for a recommendation on a fastener that would eliminate the BSR problems that they were experiencing, as well as explore the possibility of a cost savings.

SPIROL SOLUTION:

SPIROL investigated use of both a Coiled Pin and a Knurled Pin. After much review, it was decided that the inherent design of the Coiled Pin would provide many benefits to the customer in this plastic door handle.

The Coiled Pin is ideal for plastic applications because as it is inserted, the pin flexes and conforms to the host material and hole. This results in less damage to the host components than other non-flexible fasteners. In addition, since the Coiled Pin retains itself in the hole, secondary operations such as staking are not necessary. This elimination of the staking also reduces the likelihood for component damage. The spring-like action of the coils prevents component damage by absorbing the loads imparted to the assembly during and after installation.

Local Design, Global Supply.

SPIROL has Application Engineers throughout the world to assist you in your designs, supported by state-of-the-art manufacturing centers and worldwide stocking facilities to simplify the logistics of delivering your product.

Have a manufacturing issue you can't solve? Our engineering experts love a challenge. Recommending efficient solutions for your application requirements is what we do best. Give us a call or fill out the form below to connect with us!

+86 021-5046 1451

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España