Home >

Application Stories >

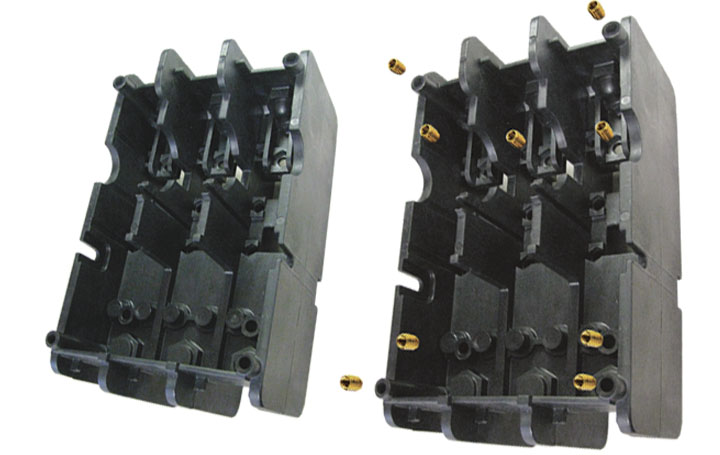

High Voltage Switch Housing

High Voltage Switch Housing

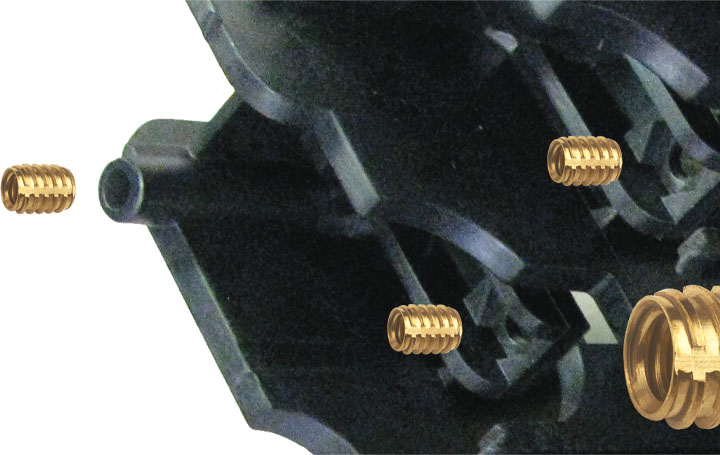

A molder of components used in high voltage controls was experiencing difficulty installing brass Inserts into their plastic parts. They required high performance Inserts with a quality installation to withstand a high torque load as well as resistance to vibration caused by constant low frequency switching. The plastic housing was designed to resist extremely high temperatures during normal operation. Accordingly, the plastic composition had a high percentage of glass and mineral fillers to withstand the harsh environment. The plastic’s resistance to melting made it exceptionally difficult to install the Inserts using heat or ultrasonic equipment. However, without properly installed Inserts, the plastic assembly failed, causing short circuits. The molder requested SPIROL’s help in determining the best Insert and most efficient installation method to meet their performance requirements.