Home >

Application Stories >

Hydraulic Brake Treadle

Hydraulic Brake Treadle

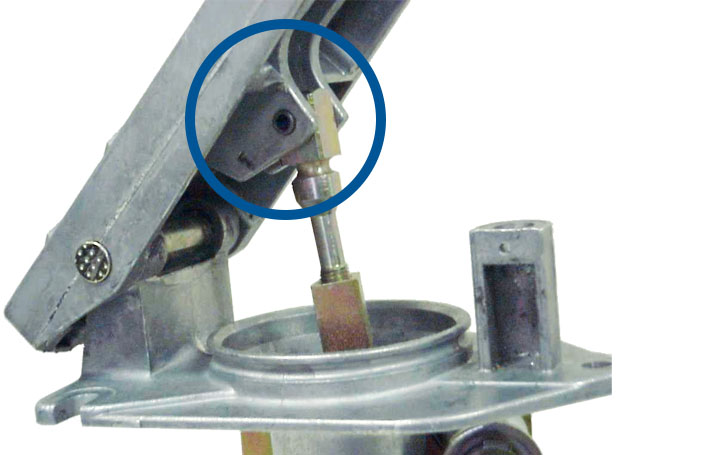

The customer was using a Solid Pin to connect the push rod and the pedal in the brake treadle application. The component is a pedal attached to a spring actuating mechanism assembly. The pedal is connected to the treadle in two locations. One location is a hinge between the pedal and the base. The other connection is between the pedal and the push rod. The push rod actuates the spring assembly by way of pedal movement. The Solid Pin is installed through holes in the aluminum casting and through a hole in the push rod. The Solid Pin presently has two clips that are installed into grooves in each end of the Solid Pin. The clips hold the free fitting pin in place and prevent the pin from falling out of the hole. The hole in the push rod also has a pressed-in bearing. The bearing is an oil-lite brass bearing and is used for galvanic corrosion resistance purposes.

The customer was interested in SPIROL providing a cost savings in this application. The customer was open to any changes to the application.