Home >

Application Stories >

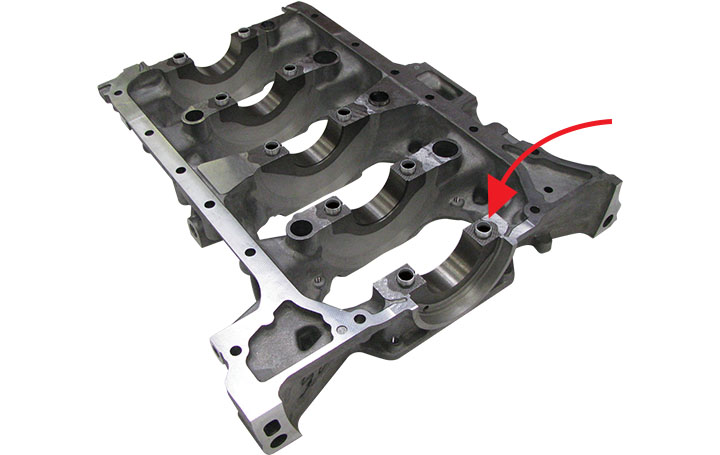

Lower Engine Block

Lower Engine Block

A lower engine block, sometimes referred to as a ladder frame or bedplate assembly, is designed to integrate the main bearing caps into a solid cast body. Most OEMs feel that producing an engine in a two-piece method offers a robust design that directly controls radial noise for improved NVH (noise, vibration & harshness). In every lower block application, some type of precision alignment is required between it and the primary engine block. In most applications with fixed bearing caps, the two pieces of the block are aligned and fastened prior to the main bore being machined. After the machining process, the two halves are disassembled to accommodate some internal sub-assembly and upon reassembly, the selected locating feature must support a two-point maximum tolerance of 50 microns.

Over the years, SPIROL has witnessed companies explore numerous alignment solutions for lower block applications. Traditionally, Machined Solid Dowels, Ground Pins, Solid Pins and/or Powder Metal Dowels have been used. Today, there are much more cost-effective options available to achieve the desired alignment between components.