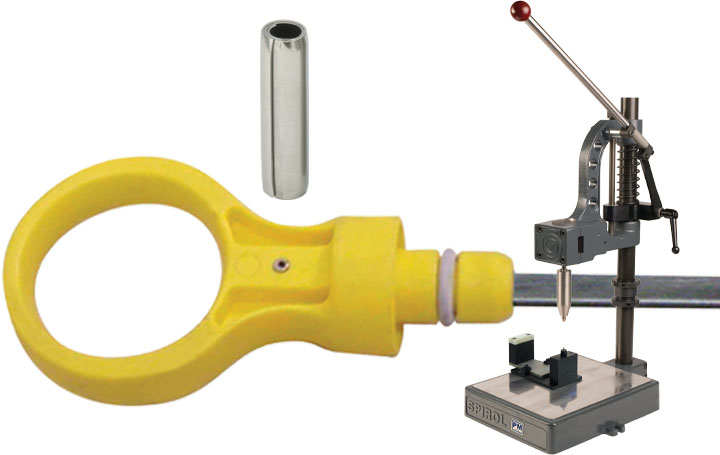

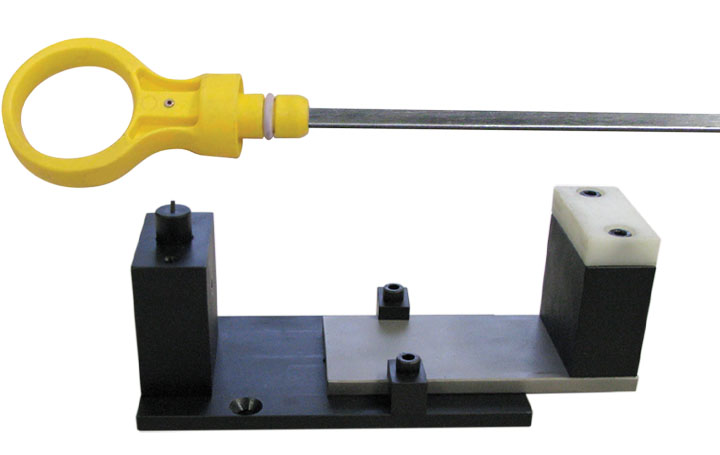

An automotive molder was molding and assembling an Oil Level Dipstick consisting of a blade and finger ring. Their objective was to be able to quickly and efficiently assemble 5,000 units per month. To do so, the company desired to establish a production cell that could accomplish this in one week. The cell also needed to be flexible enough to allow them to assemble several other low-volume items in the remaining weeks of each month.