Home >

Application Stories >

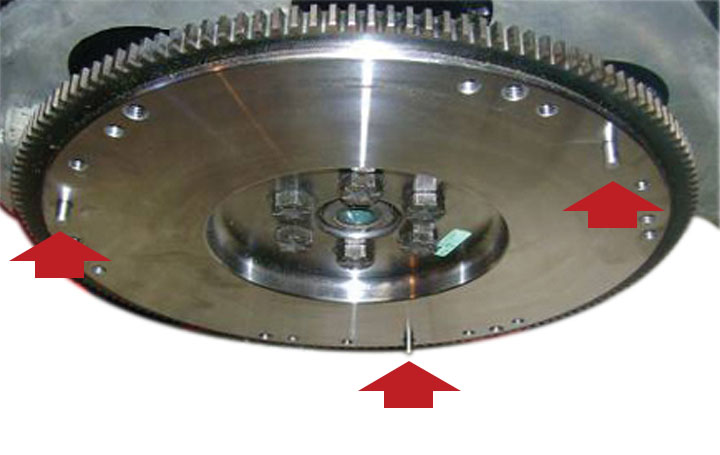

Alignment for Clutch Plate in Heavy Equipment

Alignment for Clutch Plate in Heavy Equipment

Alignment of components is critical in various powertrain and hydraulic systems. Traditionally Solid OD Ground Dowels have been used to provide the necessary alignment. However, these Ground Dowels require precision machined holes to ensure adequate interference between the Dowel and hole for retention and to keep the insertion force within a practical limit. Precision honing the holes, as compared to simply drilling the holes, results in substantially higher manufacturing costs.

In a large 36” diameter clutch plate there were (24) holes containing a series of (12) ø16mm Solid Ground Dowels and (12) ø10mm size bolts in an alternating pattern around the OD of the plate.