Home >

Application Stories >

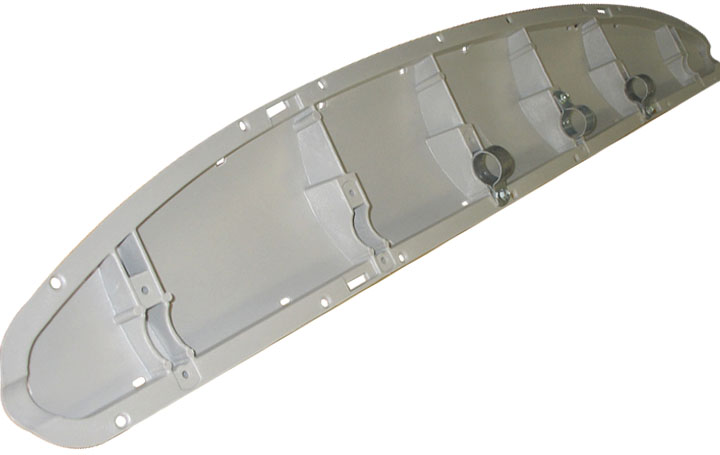

Bar Mounted Media/Map Rack

Bar Mounted Media/Map Rack

The customer was using a thread cutting screw to fasten a map rack to the safety bar of a ski lift. The application requires seasonal removal and the repeated cycle of installation and removal led to failure of the plastic boss. The customer approached SPIROL for assistance in determining the best alternative solution that would provide a reusable thread. SPIROL Engineering evaluated the customers assembly and identified a number of issues which had led to the reported failures, as well as a solution.