Home >

Application Stories >

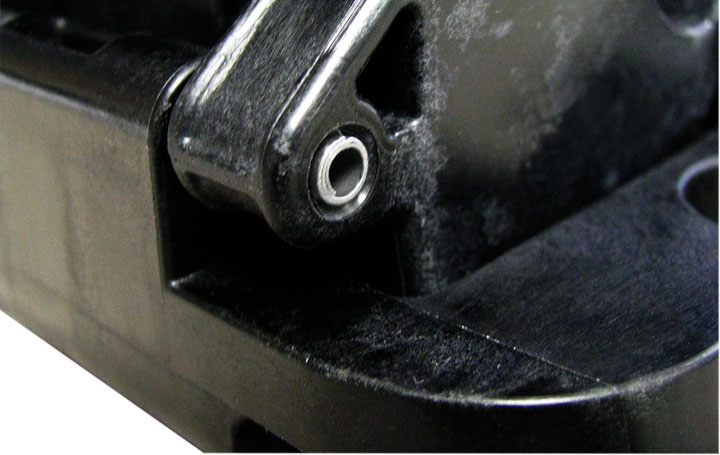

Automatic Transmission Shifter Housing

Automatic Transmission Shifter Housing

An automotive transmission shifter housing was initially designed to be attached to a floor mounted base by using a machined Solid Pin. The manufacturer recognized that the Solid Pin was expensive, and approached SPIROL for a recommendation to reduce the cost of the assembly. Both the shifter housing and the base to which it was attached were manufactured from plastic. Due to the fact that this was a mature design, the holes could not be changed as it would cost too much to modify the molds. Unfortunately this meant that a standard item could not be used, and therefore a special pin would have to be designed to accommodate the existing hole sizes.

The shifter housing was assembled by being lowered into the base and then subsequently pinned in place. The main purpose of the pin was to retain the housing to the base. Once assembled, there was limited loading applied on the pin.