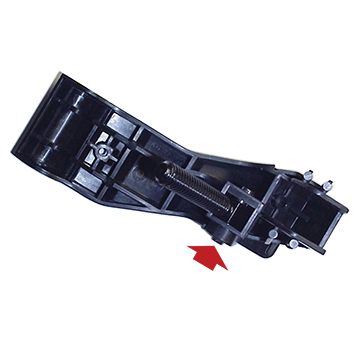

Automotive Accelerator Pedal

Application:

The manufacturer of an automotive accelerator pedal wished to reduce the total cost of their assembly by replacing a machined Solid Pin retained with a Push Nut. The Solid Pin functioned as the axle on which the pedal would rotate. The objective was to reduce the number and cost of components while concurrently simplifying assembly. The solution would have to comply with a retention criteria specified by the end user.

The solution would have to comply with a retention criteria specified by the end user.

The assembly consisted of a plastic frame and plated steel lead screw. The plastic and lead screw had to rotate freely when the pedal was depressed. Evaluation of the assembly revealed that a pin could be fixed in one component, and allowed to rotate freely within the other. Of the two components, the steel lead screw provided greater material strength as well as the longest length of engagement for retention of a pin.

SPIROL Solution:

The most cost-effective solution was determined to be a standard duty Coiled Pin that was retained within the steel lead screw, and allowed to rotate within the plastic frame. The manufacturer was able to maintain the existing hole size in the steel lead screw, and only a simple core pin change was needed to provide the clearance hole in the plastic frame.

Coiled Pins are designed such that their pre-installed diameter is larger than the recommended hole. The diameter is compressed as the Coiled Spring Pin is inserted. Once installed, it retains itself by exerting constant radial force against the hole wall as it attempts to recover back to its pre-installed diameter. Retention values can be quite high depending on the hole size, host material and “duty” of the pin. Standard duty offered the optimum balance of strength and flexibility that exceeded all of the performance requirements for this particular application.

The Coiled Pin achieved the primary goal of reducing cost and simplifying assembly by eliminating the expensive machined Solid Pin and Push Nut combination. The recommended product was within SPIROL’s standard line, and therefore provided a low cost solution that could be supplied quickly for evaluation and testing.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국