Home >

Application Stories >

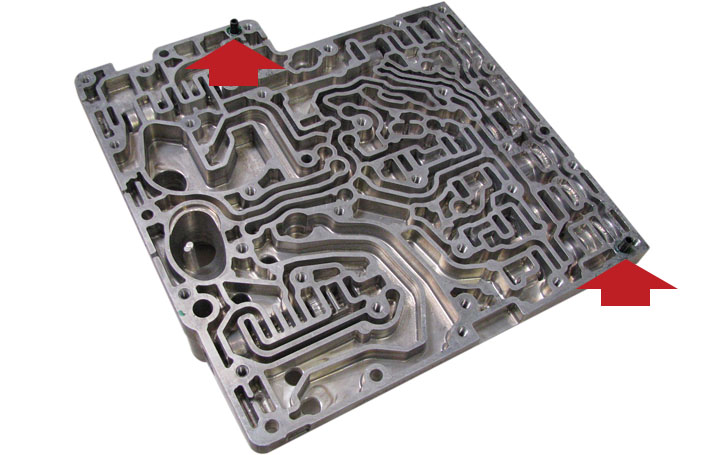

Automotive Valve Body Assembly

Automotive Valve Body Assembly

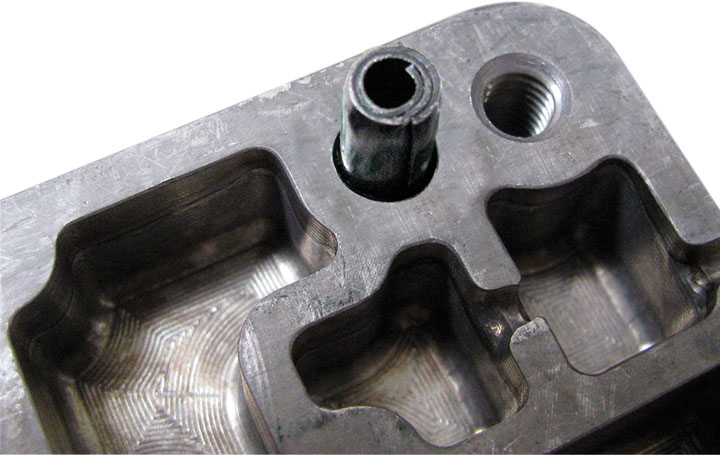

The manufacturer/assembler of an automotive valve body assembly wished to locate the upper and lower valve bodies during sub-assembly. Their intent was also to utilize locating pins during final assembly to locate the transmission case. The total cost of their assembly was being monitored very closely, and they were in search of a product which met all their alignment specifications. Machined Solid Pins and Slotted Spring Pins were trialed, but neither provided the lowest installed total cost and both were difficult to install. The Solid Pin required a very precise hole, it increased the overall assembly weight, had a higher installation force, and was more expensive overall. The Slotted Spring Pin did not provide precise enough critical alignment to the finished transmission case, and it could not be automatically fed due to fact that this type of pin is not very straight, the gap can cause nesting and interlocking, and the imperfect chamfers on the ends of the pins makes it difficult to start the pin during installation. The customer approached SPIROL for help in achieving their overall objective of reducing hole preparation time, reducing the weight of assembly, lowering installation forces, and simplifying the assembly/part feeding process within the plant.