Home >

Application Stories >

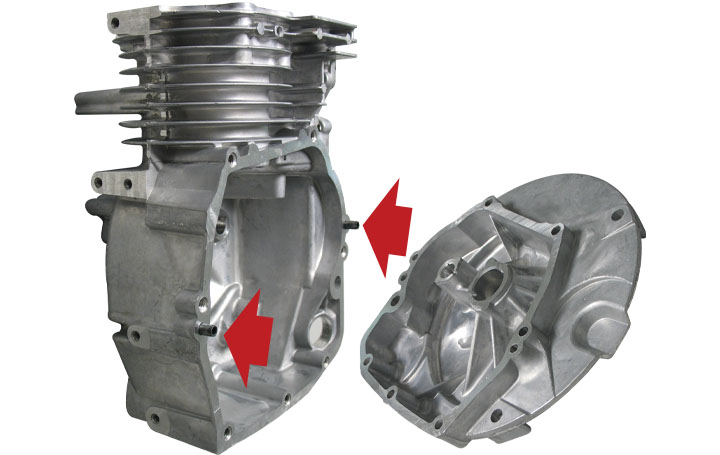

Small Engine Crank Shaft Cover

Small Engine Crank Shaft Cover

A manufacturer of small engines required a cost effective method to align a crankshaft cover to an aluminum engine block.

The manufacturer used a press-fit Ground Dowel to align the crankshaft cover to an aluminum engine block. The solution was required to hold the cover in position until permanent fasteners were installed in a subsequent operation.

Ground Dowels must be retained via a press-fit. This requires holes to be reamed, a costly process that is not efficient. Solid Dowels displace host material to achieve retention. Not only does this require high insertion force, it also introduces the potential for error in alignment to occur as the result of hole deformation. This also introduces high levels of internal stress within the hole.