Home >

Application Stories >

Reinforcement for Fuel Evaporation Canister

Reinforcement for Fuel Evaporation Canister

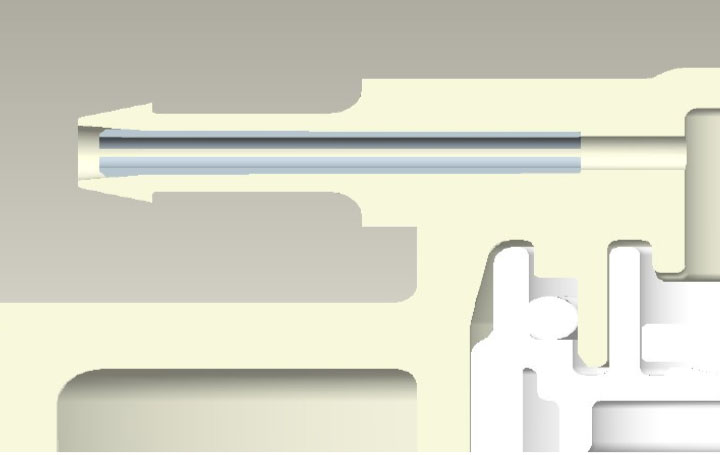

An industry leader in fuel systems designed a new evaporation canister, part of a vehicle’s emissions system. The assembly was composed of plastic, with a chamber where gasoline fumes are filtered through charcoal and a lid with a cylindrical hose fitting though which fumes are able to flow. The original design did not offer any reinforcement to the plastic hose fitting, and the OEM was concerned about its ability to maintain structural integrity over the lifespan of the fuel system.

The reinforcing component had to be self-retaining, resistant to the harsh corrosive environment, and allow fumes to flow freely through its center. The customer initially considered using Slotted Pins to reinforce the plastic tube; however they requested SPIROL’s assistance in determining the best component for their application.