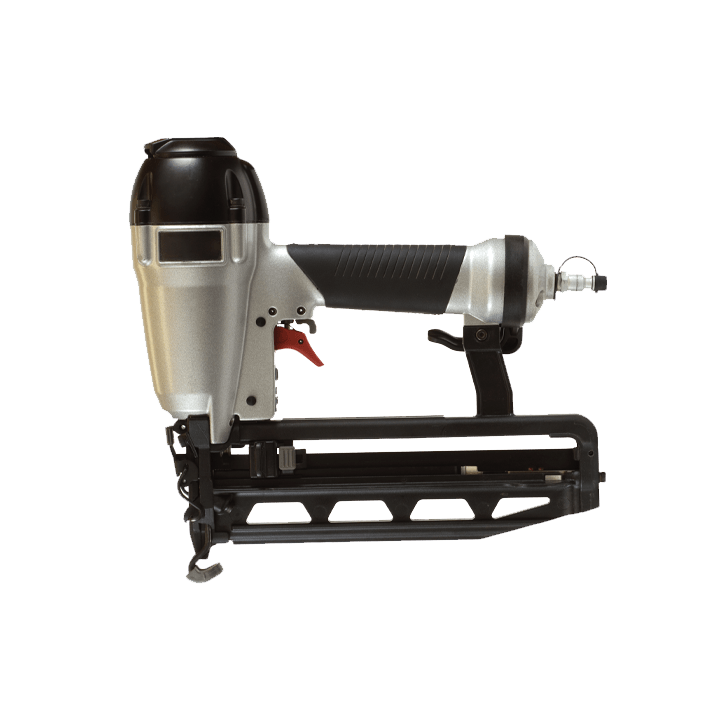

Nail Gun

A manufacturer of a pneumatic nail gun was experiencing difficulties installing a pin used to hold a steel shaft to an aluminum piston.

The steel shaft acts as the nail driver when the gun is actuated.

PRIOR SOLUTION:

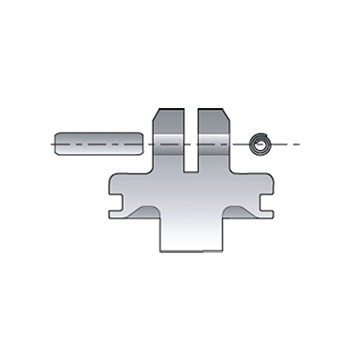

Two Slotted Pins were doubled up to pin the nail driver to a piston. In order to meet the shear requirements of the application a .125” diameter Slotted Pin was manually inserted inside a .219” diameter Slotted Pin before being pressed into the component.

The prior solution required two pins and an additional step in assembly to insert one Slotted Pin into the other. It was a difficult and time-consuming process to align the gaps of the Slotted Pins 180° opposite to each other, and then press the smaller pin into the larger pin. The Slotted Pin within a Slotted Pin resulted in high insertion forces, damaged assemblies, and difficult removal of the pins during service.

SPIROL SOLUTION:

SPIROL Engineering designed an extra heavy-duty .219” diameter Coiled Spring Pin to meet the required shear strength. This pin could be used in the application without any modification to the components.

Using a single Coiled Spring Pin eliminated the assembly operation of manually aligning and installing one Slotted Pin into another. By using one Coiled Spring Pin versus a Slotted Pin within a Slotted Pin, the insertion forces were significantly reduced. The use of a Coiled Spring Pin that is absent of a gap made it possible to completely automate the assembly process. This increased productivity and lowered the total assembled cost of the component.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국