Home >

Application Stories >

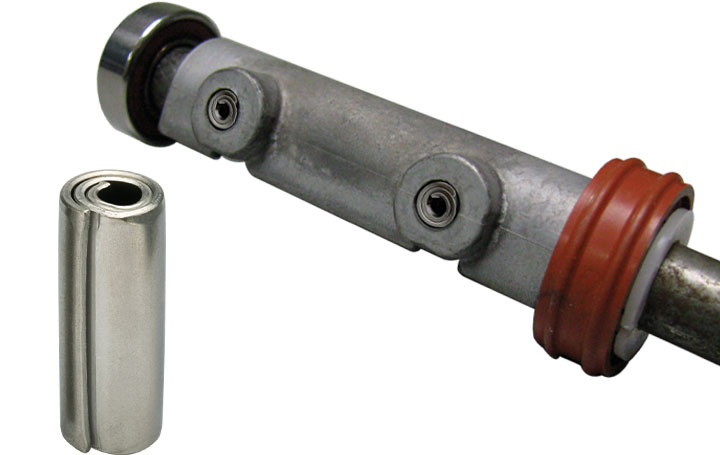

Automotive Intake Manifold Flow Control Valve

Automotive Intake Manifold Flow Control Valve

An intake manifold had been designed with four flow control valves and a stop, each affixed to a common shaft with two Slotted Pins. The valves are cast magnesium and the stop is plastic. The customer complained of poor efficiency due to nesting and interlocking of pins in their feed equipment. Quality issues had also been tied to the Slotted Pin. These issues consisted of high insertion force, skiving, cracking of the host, and increased total run-out over the shafts length. A solution was required that would improve efficiency, reduce or eliminate the occurrence of damage to the host materials, and lower insertion force to prevent deflection in the shaft.