Home >

Application Stories >

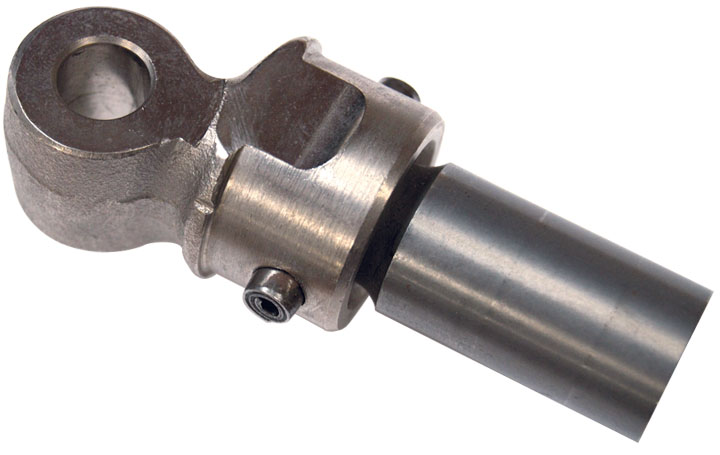

Manual Transmission Shift Linkage Shaft/Knuckle

Manual Transmission Shift Linkage Shaft/Knuckle

The designers of a shift linkage assembly for a manual transmission required a fastener to pin a shaft in a knuckle. The pin had to allow articulation of shaft and knuckle without introducing clearance between components. Clearance would result in a condition known as ‘lash’, or play in the joint. If present, this condition would be detectable when shifting. The linkage was designed for use in a high performance luxury vehicle and shifting had to be tight and responsive.

The shaft’s ball end was intended to fit within the mating knuckle. A pin would be installed through the knuckle and ball where it would function as an axle allowing rotation of the ball in a single direction. Initial plans called for a retention ring to be installed around the OD of the knuckle to prevent lateral movement, or walking of the pin within the joint. The pin would be subject to high shear load and fatigue due to torsional loading on the bar. A Coiled Spring Pin would be the best solution for use in the customers assembly.