Pressure Relief Valve

SPIROL 420 Stainless Steel Coiled Spring Pins are used in pressure relief valves to secure lift levers relative to pull rods. These valves are used to regulate temperature and pressure in residential water heaters and storage tanks.

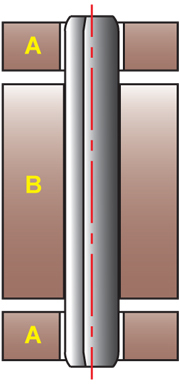

The flexibility of the Coiled Pin enables a friction fit engagement with the rod and a free fit with the lever. Since the rod provides more engagement length than the lift levers, it is better suited to be used as the friction fit portion of the hinge, as shown in Figure 1.

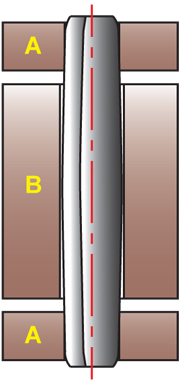

When properly employed, this spring feature of the Coiled Pin can be used to design better free-fit and friction-fit hinges as well as improve retention and reduce the incidence of lateral movement. This not only provides the proper “feel” of the hinge, but can also help ensure that the pin stays in place due to the “ballooning effect,” as shown in Figure 2.

In addition to excellent balance of strength and flexibility, another benefit of SPIROL’s Coiled Pins that is essential to many pressure relief valves, is that they come standard in various types of stainless steel. This provides the necessary corrosion resistance required by many pressure relief valves since they are can be exposed to water.

Even though the pin is often one of the smallest and least expensive components in an assembly, it is critical to design in the optimal pin configuration to ensure proper operational and functional excellence at the lowest installed cost. With over 65 years of technical expertise related to joining and assembly, SPIROL is well positioned to assist with design of the pin to ensure our customers’ parts go together and stay together for the intended life of the assembly.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국