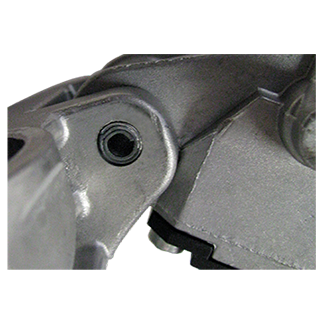

Automotive Steering Column Assembly

The pin is used in an automotive steering column assembly to act as a hinge retaining the aluminium housing and gear motor.

Prior Solution:

The manufacturer was using an 8 x 45 standard duty phosphate coated coiled pin from a competitor. The customer was experiencing high levels of failures and scrap during the installation process due to the high insertion forces needed to assemble the pin within the application. As well as the high scrap levels, the customer was also experiencing poor productivity due to increased down time.

Due to the fact that this was a mature design, the hole sizes could not be changed as it would have cost too much to modify all of the involved parts and perform revalidation tests. Also the customer was using automated assembly equipment that had been set up to operate within a certain range of force in order to ensure that the housing would not be damaged by application of too much load, but ensure the retention of the pin.

Once assembled there was very little load actually applied directly to the pin.

SPIROL Solution:

SPIROL Engineering analyzed the application and identified that two solutions could be proposed. A light duty Coiled Spring Pin as well as a controlled insertion standard duty Coiled Spring Pin. Due to the fact that all validation tests had been performed previously with the standard duty pins, moving to a lower shear pin such as the light duty pin would have required expensive revalidation tests. Additionally the phosphate coating added to the increased insertion force and cost. The SPIROL solution was to go with the controlled insertion force standard duty Coiled Spring Pin without phosphate coating.

Benefits:

The recommended pin provided an insertion pressure at a level that would not damage the assembly, and due to being the same shear as the original pin, would save the customer from performing costly shear test validations. The pin also reduced the customers cost by removal of the coating. With the controlled insertion the pin also improved productivity, and eliminated scrapped assemblies.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국