Home >

Application Stories >

Alignment Pins for Diesel Fuel Assembly

Alignment Pins for Diesel Fuel Assembly

A manufacturer of diesel fuel assemblies required a pin that had higher shear strength than the 3-coil Coiled Pin that was being used in order to withstand the torque generated during disassembly.

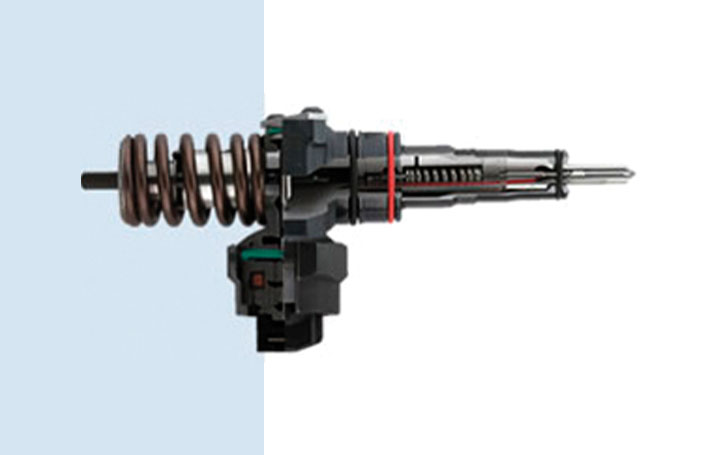

The customer currently uses a 3-coil Coiled Spring Pin to align three components within a diesel fuel injector. The pins are pressed into holes in the top and bottom of the center component, with a slip fit in the two mating components. The components are assembled, and then carefully placed into the injector housing.

The pins position the individual parts such that a fuel hole is aligned amongst each of the components. Fuel passes through these holes to the end of the injector and exits the injector nozzle to flow into the cylinders of an internal combustion engine.

In addition to aligning the components, it is imperative that the pins do not cause the host material to bulge and that debris is not generated during installation. Traditional Solid Pins have been discounted as a viable solution in the past for several reasons. Grooved Pins require too high an insertion force and distort the face of the component around the hole preventing a clean mating surface between the parts. Knurled Pins have the potential of introducing slivers into the assembly if the knurls shear off during installation. Finally, Straight Dowel Pins require extremely tight tolerances to ensure a proper fit, and drastically increase the total installed cost of the components.