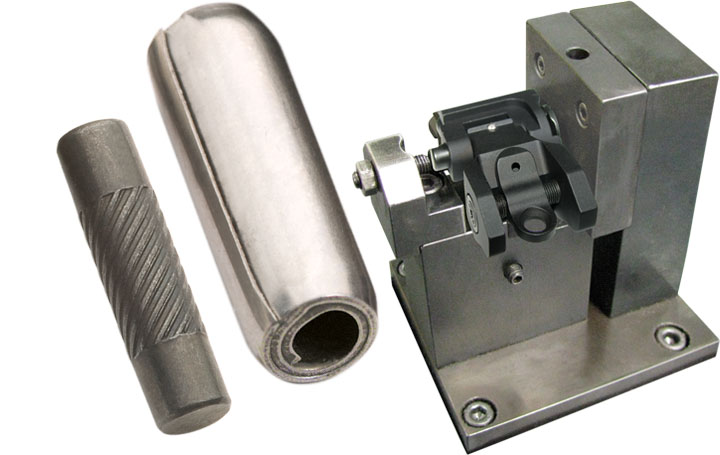

A manufacturer of after-market Tactical Rifle Sights had been manually assembling a folding rear sight. The sight contained two Solid Dowel Pins, and a Slotted Spring Pin. The Solid Pins were manually installed in a multistage process. Due to manufacturing tolerances, the pins were occasionally loose, requiring an additional operation to ensure retention. The Slotted Pin was also manually installed. This process required the operator to pre-compress a spring with a clamp, then "start" the Slotted Pin into the hole. The sub-assembly was then placed under a manual press to complete the installation. The pin was not easy to handle due to its small diameter resulting in a slow, tedious process. Any misalignment of the pin resulted in damage to the assembly, therefore alignment and proper pin location was critical.