卷制弹性圆柱销与直槽弹性圆柱销的区别

作者

下载白皮书什么是弹性圆柱销?

弹性圆柱销,也常被称为张力销或滚销,是一种用于将装配件的两个或多个部件固定在一起的机械紧固件。弹性圆柱销是空心管状部件,设计时尺寸大于孔径,通常由各种类型的弹簧钢或其他材料制成。

弹性圆柱销与传统实心销的主要区别在于,其径向刚度显著低于主体材料。实心销可以拥有光滑无缝的表面(如定位销),也可设计带有凹槽、滚花或倒钩等保持特征。实心销通常通过使主体材料变形或位移来固定。然而,在销钉经过精密磨削且孔经过精密镗削的情况下,精密磨削的实心销与孔之间的配合可以被精确控制到轻微间隙和微小过盈之间,这种配合不会导致销钉或主体材料发生变形。但是,销钉和孔都需要进行精密磨削和镗削,使得这一紧固方案成为成本最高的选项之一。

另一方面,弹性圆柱销可以承受比刚性实心销更大的孔径公差。由于其弹性,弹性圆柱销不仅制造成本更低,而且孔的准备工作也更加简单和低成本。较低的刚度还带来了另一个优点——正确选择的弹性圆柱销不会损坏主体孔——因此,可以在无需重新加工部件的情况下对其进行维修。

弹性圆柱销有两种基本类型:直槽弹性圆柱销和卷制弹性圆柱销。

直槽弹性圆柱销

直槽弹性圆柱销的特点是C形截面和一条平行于轴线的槽。虽然其确切起源未知,但在整个现代历史中,它们一直是机械装置中的一个概念。随着时间的推移,通过各种行业标准,它们已广泛用于多种不同类型的应用之中。

目前有几种活跃的行业标准,但其中四(4)种占主导地位,占据了大多数直槽销的需求:ASME B18.8.2, ASME B18.8.4M, ISO 8752 和 ISO 13337。

卷制弹性圆柱销

卷制弹性圆柱销以其2¼圈的截面而著称。卷制圆柱销的历史更为清晰。它是由SPIROL公司创始人Herman Koehl于1948年发明的,专门用于应对具有强烈振动和动态载荷的应用——喷气发动机的转子。与容易在剧烈振动下松动的传统紧固件(如螺母和螺栓),以及将动态载荷传递给孔壁从而影响销钉固定的刚性实心销不同,Koehl先生设计了一种既能有效抵抗使用过程中产生的力,又能灵活吸收这些力的销钉,以保护孔材料并保持装配件完整。卷制圆柱销有三种不同的规格,可为不同的应用场景和主体材料提供最佳的强度与弹性组合。

最常用的卷制圆柱销行业标准包括 ISO 8750, ISO 8748, ISO 8751以及 ASME B18.8.2 和 ASME B18.8.3M。这些标准彼此差异不大,被认为实际上是等效的。

卷制弹性 圆柱销

直槽弹性 圆柱销

物理特性与区别

截面

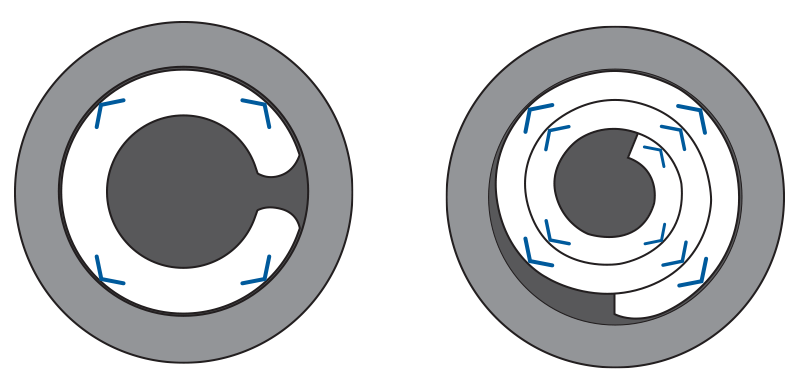

卷制弹性圆柱销与直槽弹性圆柱销的主要区别在于截面形状,如图1所示。直槽销是一个C形销,通常由较厚的带状材料滚压而成,而卷制圆柱销则由较薄的带状材料滚压而成,在相同的标称直径下,形成典型的2¼圈截面。这种区别的关键影响是销钉的弹性。直槽销只能在一定范围内卷曲,之后它的缺口就会闭合,实际上变成了一个刚性的实心管。槽口允许直槽销在安装期间吸收孔的制造公差,但安装后的冲击和振动无法得到缓解,因为进一步的卷曲受到闭合槽口的限制。这可能导致接头过早失效和主体部件损坏。

而得益于卷簧近乎无限的弹性,卷制圆柱销则可以超越初始安装时的过盈,配合进一步卷曲。事实上,当为装配件选择了合适的卷制弹性圆柱销时,销钉将无限期地吸收振动和冲击力,并保护孔材料,以最大限度地延长装配件的使用寿命。

图1

直槽弹性圆柱销(左)与卷制弹性圆柱销(右)的截面示意图显示径向张力的不同

图2

相互卡扣的直槽弹性圆柱销示例

槽口/接缝

另一关键区别在于钢带末端的设计方式。对于直槽销而言,这是槽口。在某些配置中,槽宽等于钢带厚度本身(ISO 8752),这意味着销钉可以相互卡扣或嵌套在一起,如图2所示。在高度自动化的装配线上,应避免使用此类直槽销,因为这将导致送料设备堵塞。

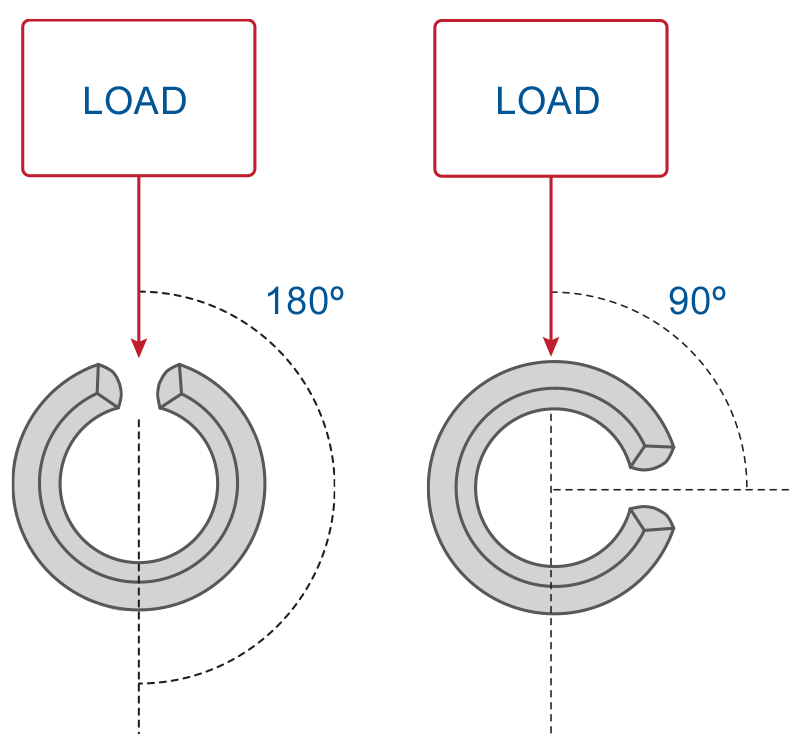

而卷制圆柱销,由于有多层材料缠绕,具有平滑的接缝而非开放槽口(图3)。封闭截面不仅防止销钉相互卡扣或嵌套,还提供了便于旋转的平滑表面,这对于铰链应用尤其有用。具有更均匀截面的另一个好处是卷制圆柱销的强度不受方向的影响。而C形直槽销的剪切强度会有大约5%变化幅度,具体取决于载荷是否与槽口对齐(0°或180°(图 4)).

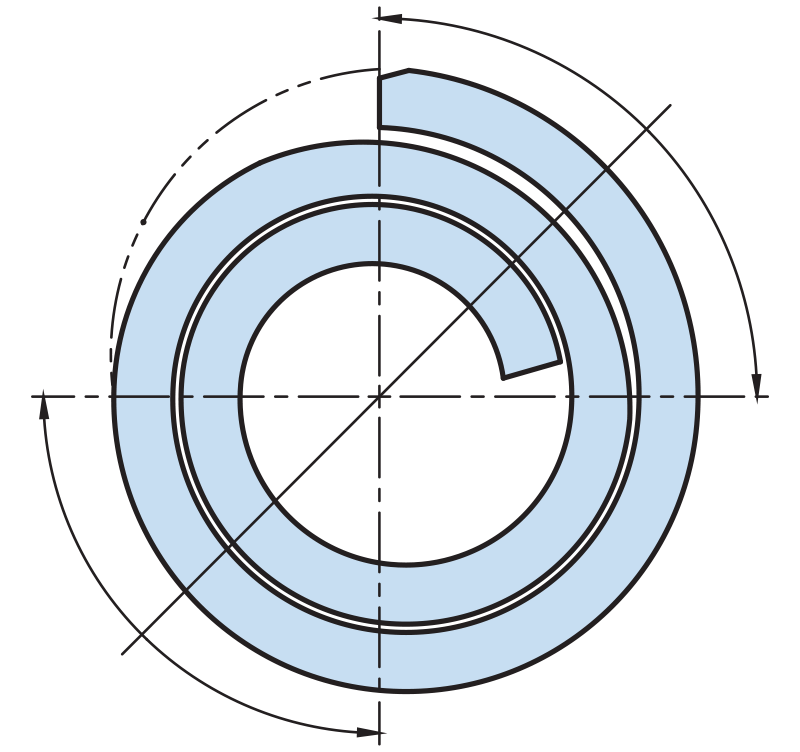

图3

卷制弹性圆柱销的截面

图4

槽口方向对直槽弹性圆柱销剪切强度的影响约为5%

倒角

某些配置的直槽销规定有“小于标称销钉直径”的倒角直径(ISO 8752)。这会阻止销钉在安装前自行与孔对齐,也不能补偿被销钉连接的部件间的错位。而其他直槽销行业规范则采用更受控的倒角直径设计,使其小于孔,并留有一定的余量,以便于装配。

所有卷制圆柱销的倒角直径均规定为比孔小,并具有特定的余量。卷制圆柱销的倒角通过平滑过渡设计以实现无障碍装配。

垂直端面

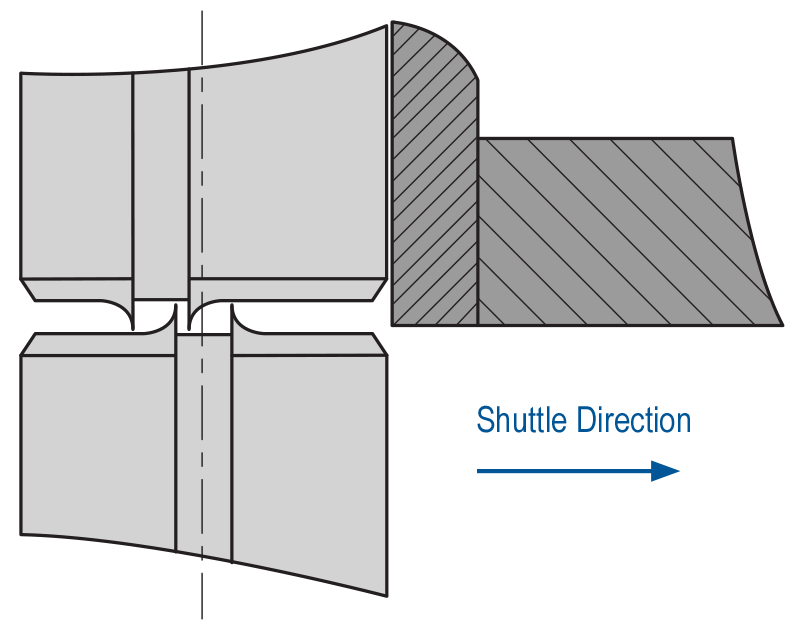

由于制造方法的不同,直槽销的两端往往并非完全垂直于其轴线。这会在自动化送料过程中造成阻碍,因为堆叠的销钉可能会抓取相邻部件,导致堵塞。这也可能是由于销钉两端在制造过程中有时产生的小“凸起”造成的(图5)。

而卷制圆柱销具有垂直端面,能够与安装冲头/压头配合时自动对齐。这可保证销钉保持直线,且安装时向孔施加均匀的力。

图5

有些直槽销两端有小“凸起”可能会导致自动化送料器堵塞(此处为夸张表达以示说明)

基于应用的销钉推荐

动态应用

在动态应用中,卷制弹性圆柱销的表现优于所有其他类型的压装销。在动态应用中,销钉需要承受振动、冲击或撞击,并且需要能够吸收这些作用力,以尽可能延长服务寿命。

图6

卷制弹性圆柱销在安装后仍保持弹性可吸收冲击与振动并延长组件的使用寿命

卷制圆柱销专门设计用于在插入后保持灵活性并吸收变化的载荷和振动(图6)。研究表明,在疲劳测试中,无论是在1)无限寿命的极限载荷,还是在2)设定载荷下的循环次数上,卷制圆柱销明显优于直槽销。

直槽销的弹性有限——其中大部分在安装时就被消耗掉了。一旦安装完毕,直槽销几乎没有剩余的间隙宽度来吸收任何变化的载荷。当槽口关闭时,直槽销就变成一个刚性的实心管,并像实心销一样将载荷直接传递给主体。这可能会损坏孔,使得部件无法使用或需要返工。

另外,槽口方向也会影响直槽销的服务寿命。通过测试发现,当槽口与载荷方向呈90°时,直槽销的服务寿命可减少大约50%(图4)。而卷制圆柱销的服务寿命则不受方向的影响。

自动化装配

在高度自动化的环境中,实现一致的安装质量并防止生产线停工至关重要。卷制圆柱销由于其独特功能组合,最适合高度自动化的环境,因为其没有槽口,垂直端面,压制成型的倒角以及一致的安装力需求,可实现无障碍安装并最大程度减少停机时间。此外,卷制弹性圆柱销的性能不受其所负荷方向的影响。

中国

中国 马来西亚

马来西亚  韩国

韩国  美国

美国  加拿大

加拿大  英国

英国  德国

德国  墨西哥

墨西哥  巴西

巴西  捷克共和国

捷克共和国  法国

法国  西班牙

西班牙