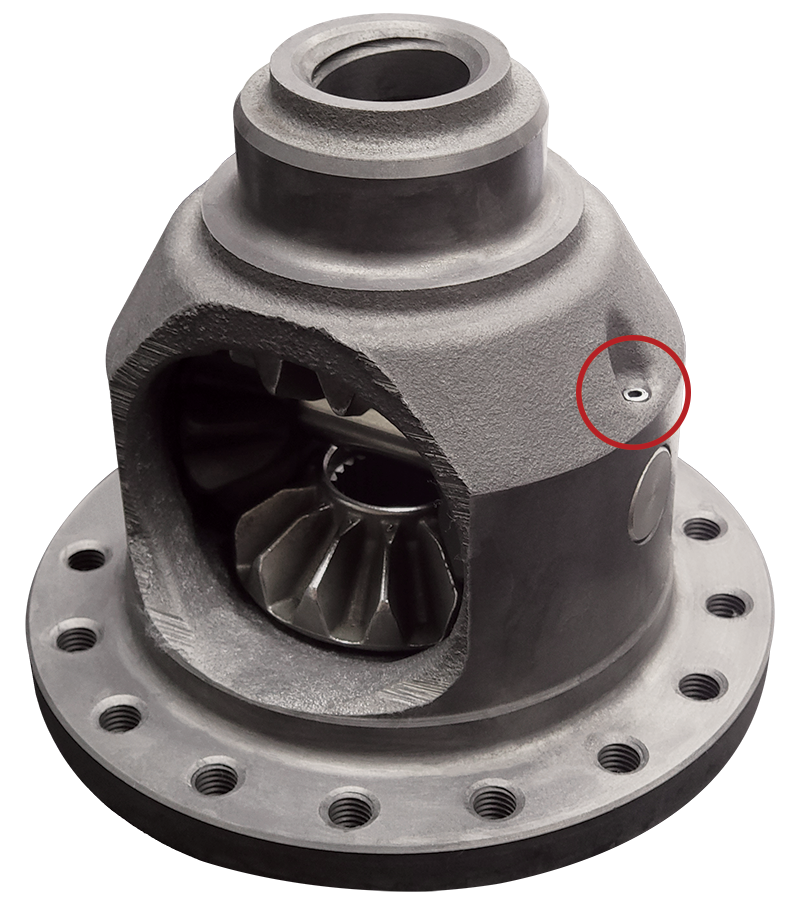

Differential Carrier Assembly

Traditional Solution

To retain a pinion shaft in a differential carrier, a Solid Pin is commonly used in precision drilled and reamed holes. Solid Pins require a very strict diameter tolerance for a controlled interference and therefore additional machining (reaming) needs to be done after drilling which increases the cost of the assembly. Some manufacturers use a Solid Pin with a knurled end to be able to loosen the tolerances slightly and have only a small portion of engagement for a lower installation force.

SPIROL Solution

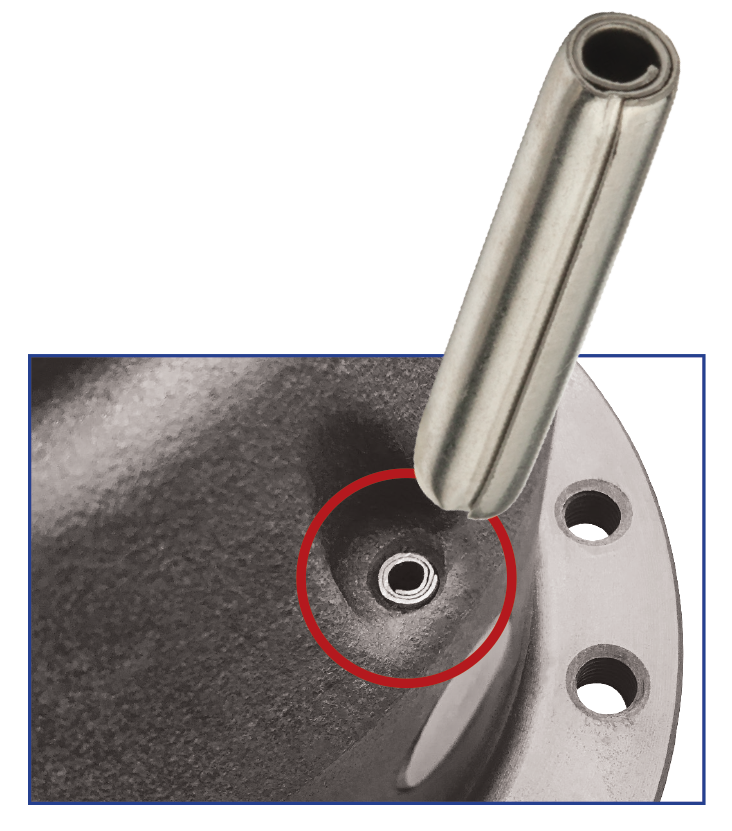

SPIROL’s Application Engineering Department evaluated the application and recommended a Coiled Spring Pin as an alternative to the commonly used Solid Pin. The pin in this application does not see significant shear force loading because the internal pinion gears are rotating freely on the shaft and transfer only minimal friction torque onto the pin. Standard high carbon steel material can be used, as the differential is an oil rich environment and does not require any corrosion resistance properties.

A big factor with differential assemblies is serviceability. The Coiled Pin does not damage the host when installed thanks to its flexibility. In addition, the Coiled Pin and can be easily removed with a punch when installed in a through hole – a recommendation given to anyone designing a differential.

Coiled Spring Pin Benefits

The Coiled Pin has multiple benefits for the application that makes it an ideal choice. The Coiled Pin can accommodate a much wider hole tolerance than Solid Pins. As a result, reaming is no longer needed – which lowers the hole preparation cost significantly. In fact, Coiled Pins can be inserted into a hole as cast, when using a die casting process, eliminating the drilling process all together.

As a functional spring, the Coiled Pin conforms to the hole and exerts a permanent radial force. This keeps the assembly in a constant state of preload, eliminating any potential of mechanical clicks or rattles.

The Coiled Pin also lends itself towards trouble-free automatic installation. Because it has no gaps, it can not interlock and cause jams in the equipment. Given its symmetrical configuration, the Coiled Pin does not have to be oriented – unlike a partially knurled Solid Pin that needs to be vision oriented due to the lack of significant orienting features. Another benefit of the Coiled Pin is a smaller and consistent installation force which allows the customer to use a smaller pneumatic cylinder within the installation machine.

By incorporating the Coiled Spring Pin rather than a partially knurled Solid Pin to retain the pinion shaft within the differential carrier, the customer will benefit from trouble free installation at the overall lowest installed cost of the assembly.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국