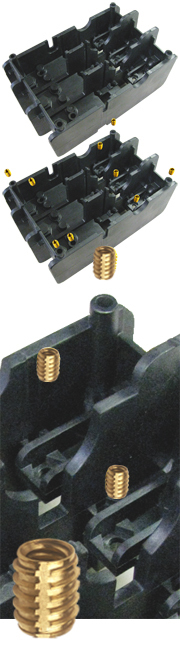

High Voltage Switch Housing

Application:

A molder of components used in high voltage controls was experiencing difficulty installing brass Inserts into their plastic parts. They required high performance Inserts with a quality installation to withstand a high torque load as well as resistance to vibration caused by constant low frequency switching. The plastic housing was designed to resist extremely high temperatures during normal operation. Accordingly, the plastic composition had a high percentage of glass and mineral fillers to withstand the harsh environment. The plastic’s resistance to melting made it exceptionally difficult to install the Inserts using heat or ultrasonic equipment. However, without properly installed Inserts, the plastic assembly failed, causing short circuits. The molder requested SPIROL’s help in determining the best Insert and most efficient installation method to meet their performance requirements.

SPIROL Solution:

SPIROL Engineers reviewed the application, and recommended that the molder change from the current Inserts to SPIROL Series 13 Self-Tapping Inserts. The hole size in the molded part did not require any modification to accommodate the Self-Tapping Inserts. The manufacturer was also able to utilize their existing X-Y fixture tooling for part positioning. The Model TA Automatic Insert Driver was installed in place of their ultrasonic unit – almost a direct bolt-in – and production resumed immediately. The Thread Cutting Inserts were easy to install into the hard plastic component, and they exceeded the performance requirements of the assembly.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국