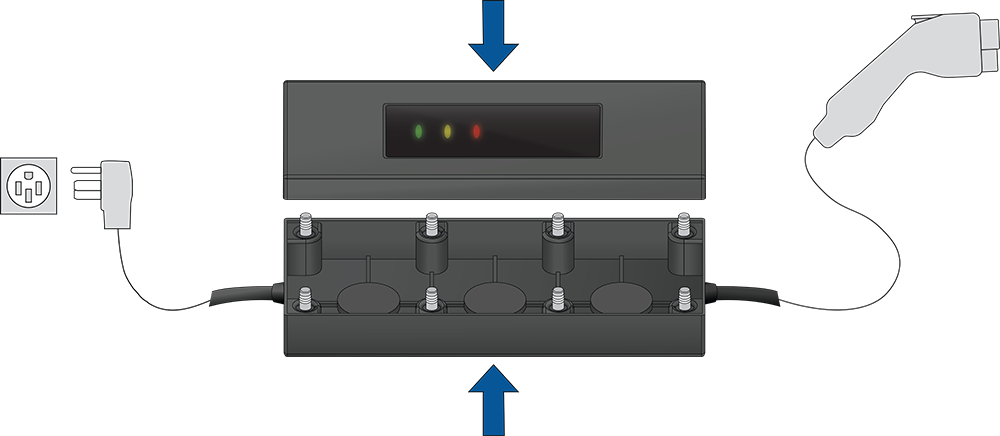

In-Cable Control Box (ICCB)

Application:

An automotive manufacturer was designing a Mode 2 charging cable assembly for electric vehicles. The manufacturer wanted permanent water sealing protection for the In-Cable Control Box (ICCB) which facilitates safe communication between the electric vehicle and charging port. The design team was investigating permanent retention mechanisms to create a seal around the internal gasket that protects the inner electrical components of the plastic ICCB housing. They were deciding between using adhesives or traditional metal fasteners.

SPIROL Solution:

SPIROL Engineering recommended using eight (8) SPIROL Series BP100 Press-N-Lok™ Pins to fasten the plastic ICCB housing. These permanent Solid Pins have barbs that provide superior retention in plastics, and they are designed to be hidden in the final product. Press-N-Lok™ Pins are post-mold installed after the plastic has cooled in two stages. First, the pins are pressed into one half of the plastic housing. Next, the other half of the housing is aligned with the exposed pins and pressed into place. As the pins are pressed into the housing, the barbs displace the plastic host material. After installation, the plastic naturally backfills behind the barbs to lock the pins in place.

Press-N-Lok™ Pins allow for a more efficient and cost effective assembly process compared to adhesives. The cost of presses to install Press-N-Lok™ Pins are significantly less than the cost of adhesive installation equipment. Furthermore, assembly is quicker and cleaner with Solid Pins because they don’t require a secondary curing process like adhesives.

The charging cable manufacturer cut production costs and reduced cycle times by using SPIROL’s Press-N-Lok™ Pins instead of adhesives to secure the plastic In-Cable Control Box.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

SPIROL Series BP100 Press-N-Lok™ Pin

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국