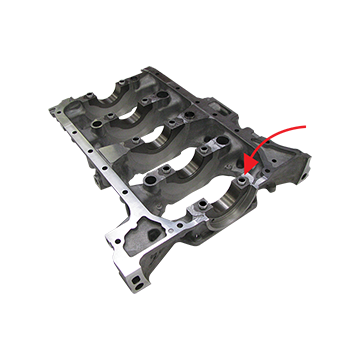

Lower Engine Block

A lower engine block, sometimes referred to as a ladder frame or bedplate assembly, is designed to integrate the main bearing caps into a solid cast body. Most OEMs feel that producing an engine in a two-piece method offers a robust design that directly controls radial noise for improved NVH (noise, vibration & harshness). In every lower block application, some type of precision alignment is required between it and the primary engine block. In most applications with fixed bearing caps, the two pieces of the block are aligned and fastened prior to the main bore being machined. After the machining process, the two halves are disassembled to accommodate some internal sub-assembly and upon reassembly, the selected locating feature must support a two-point maximum tolerance of 50 microns.

Over the years, SPIROL has witnessed companies explore numerous alignment solutions for lower block applications. Traditionally, Machined Solid Dowels, Ground Pins, Solid Pins and/or Powder Metal Dowels have been used. Today, there are much more cost-effective options available to achieve the desired alignment between components.

Spring Alignment solutions, such as Spring Dowels, Dowel Bushings and Coiled Pins, should be considered for any alignment application because they offer the lowest installed cost. In applications with very tight positional tolerance requirements (less than or equal to 50 microns), there will be a need for precision alignment unless the manufacturer takes special care with hole processing. For precision alignment scenarios, SPIROL’s GD100 Ground Hollow Dowel is a fantastic alternative to Machined or Powder Metal Alignment Pins. SPIROL’s Ground Hollow Dowels are designed to be direct replacements for standard Ground Solid Dowels per ISO 8734. They are used where centerline tolerance and precision alignment are required and maintain critical alignment within 20 µm.

For this particular application, SPIROL Engineering recommended a standard ϕ10mm Ground Hollow Dowel to replace a Solid Machined Dowel. In doing so, the customer reduced their insertion forces and reduced the weight of the Dowel by over 50%. In addition, they were able to secure over $100,000 in annual cost savings!

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국