Retaining Pin in Surgical Instrument

As one of the leading manufacturers of miniature pins (pins with a diameter less than 1.5mm), SPIROL has developed a high level of expertise installing these pins automatically. Manual installation of miniature pins usually involves the use of a magnifying glass, very small tools, and a dextrous and patient technician. The process is tedious and time consuming and the scrap rate often exceeds 10% due to part damage from unsuccessful installation attempts.

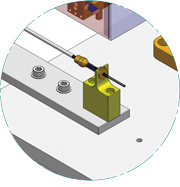

SPIROL was approached by a surgical tool manufacturer to review an assembly that required a 0.8mm (.031”) diameter stainless steel Solid Pin to affix a nylon cylinder to a shaft. The assembly consisted of an outer tube, inside of which was a smaller hollow shaft, and inside that was a solid rod. At installation, the pin had to negotiate from one side of the cylinder to the other, through all components of the assembly. The Solid Pin was a specialty item with an extremely tight OD tolerance, and the cylindrical part required a tightly toleranced hole to allow for pin installation and retention. The internal components were designed to allow clearance for the pin. SPIROL’s challenge was to provide an installation solution that eliminated manual handling of the pin by the Operator while providing repeatable, quality installations.

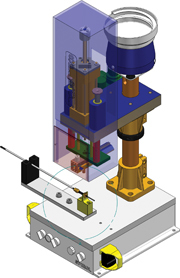

Based on the application requirements, SPIROL Engineering recommended a Model PR semi-automatic pin insertion machine. A highly polished, continuously welded, precisely tooled vibratory feed bowl was provided to deliver the pins to the retractable insertion head one at a time and place them into “ready position” for installation. Understanding the medical device industry’s cleanliness requirements, the insertion head and all components that contact the pin and/or assembly were made of 300 series stainless steel or electroless nickel plated tool steel. Exhaust from the pneumatic cylinders passed through a coalescing filter to remove particulates. These design enhancements allow use of this machine in a clean room environment.

Additionally, with the Model PR machine, the operator does not have to touch the miniature pins in any way! A specially designed fixture nest was provided which allows the components to be pre-assembled and placed into the nest ensuring proper alignment of the component holes throughout the entire assembly process. Upon machine activation, the insertion head advances close to the hole to be pinned, installs the pin, retracts and resets.

The tedious nature of the previous assembly process was eliminated, and the efficiency has more than tripled. The scrap rate at installation is near zero.

In keeping with SPIROL’s objective to provide the best possible value, SPIROL’s Applications Engineers carefully reviewed the entire assembly and offered a Coiled Spring Pin as an alternative to the Solid Pin. The Solid Pin was extremely expensive, had a long lead time, and required the hole tolerances on mating parts to be tightly controlled. (This made the mating parts expensive to produce as well.) The Coiled Pin was approximately 90% less expensive than the Solid Pin and allowed a much broader tolerance range in the holes – further reducing the cost of the assembly. The smooth, swaged chamfers allow easier entrance of the pin into the hole, eliminating installation scrap relating to pin misalignment.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국