Surgical Torque Limiter

Customer Challenge:

A manufacturer in the medical industry approached SPIROL in their quest to reduce costs and simplify the assembly process of a stack of Disc Springs used in a high-speed torque limiter surgical instrument. The Disc Spring Stack needed to generate a preload of 150 Newtons and a final load of 750 Newtons. In addition to the high cost of the current Disc Spring Stack, the manufacturer was having difficulty assembling the tiny Disc Springs into a stack. When working with very small Disc Springs, in this case less than Ø13mm, it can be difficult to efficiently assemble tiny Discs into a stack in the proper orientation when in a production environment.

SPIROL SOLUTION:

SPIROL’s Application Engineers reviewed the manufacturer’s performance requirements and assembly challenges with the current Disc Springs while considering the cost-reduction initiative and designed a custom Disc Spring to meet all three (3) expectations:

- The custom Disc Spring was designed with a higher cone height than the standard Disc Spring which created greater force in a smaller area.

- By adjusting the manufacturing parameters of the outer diameter, inner diameter, thickness and height of the Disc Springs, the specific performance characteristics of required force within the assembly parameters of the Disc Spring Stack were achieved.

- The custom stack design lowered stresses within the final assembly.

- SPIROL supplies the custom Disc Springs pre-stacked in the required configuration and packaged in shrink wrap with a perforated tab. The assembler simply has to take a stack of Disc Springs out of the box, place it into the assembly, and pull the tab. In addition to simplifying the assembly process by eliminating the need for the assembler to manipulate the tiny, individual Disc Springs with their hands, having the Discs pre-stacked in the proper orientation/configuration prevents the assembler from accidentally placing one of the individual Disc Springs in the wrong configuration. A wrongly configured Disc Spring would change the force/deflection characteristic of the stack, which could be disastrous for the performance of the surgical instrument.

SPIROL’s custom designed solution enabled the stack to contain two (2) fewer Disc Springs than the manufacturer’s original design. With fewer parts in each stack, an immediate cost saving was realized. In addition, human errors were eliminated, and production rates increased by having the Disc Springs delivered pre-stacked and ready for assembly.

SPIROL® pre-stacked Disc Spring

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

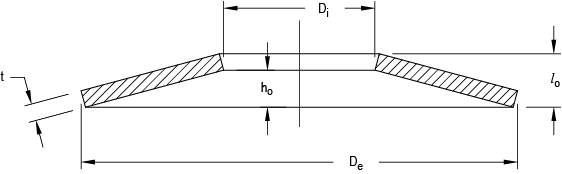

Dimensional Drawing of a Disc Spring

De = External Diameter of the Disc

Di - Internal Diameter of the Disc

Io = Free Height of the Disc

t - Material Thickness of the Disc

ho = Free Cone Height of the Disc

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España