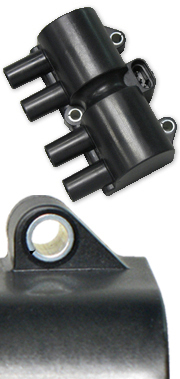

Automotive Ignition Coil

Application:

A manufacturer of automotive ignition coils approached SPIROL seeking a cost effective alternative to a machined brass Compression Limiter. Preferred method of installation was molded in. Compression Limiters were required to protect the integrity of the plastic case when bolting to the mating component. Three limiters were required per coil, one of which would protrude from the base to double as an alignment feature. For this reason, the end customer specified a high retention value to ensure the protruding Compression Limiter maintain its position.

SPIROL Solution:

The elimination of brass offers the most significant cost savings. Steel can provide the necessary strength at a much lower cost. Compression Limiters can be manufactured of low or high carbon steel and delivered soft or hard dependant upon fastener grade. Method of manufacture is the second component of cost that can be reduced. Machining or cutting operations are typically more expensive than forming. The best way to reduce the customer’s cost was to convert them from the machined brass component to a roll formed steel Compression Limiter.

SPIROL Engineering designed a rolled steel Compression Limiter to meet the customer’s specific requirements. The Compression Limiter was designed with a closed seam to ensure that plastic could not migrate to the ID where it may interfere with bolt installation. Wall thickness was selected to provide columnar strength sufficient to resist the compressive load of a Class 9.8 bolt. A radial groove was added about the part’s circumference and centered. The radial groove fills with host material during the molding process that yields high resistance to lateral movement.

SPIROL’s roll formed steel Compression Limiter provided a substantial cost reduction while meeting all of the performance requirements. Roll formed Compression Limiters are typically designed to function with Class 9.8 bolts. A variety of finishes can be provided to meet specific requirements. The retention groove provides excellent resistance to lateral movement at significantly less cost than machined components with similar features. Steel also eliminates lead in compliance with current environmental standards. Further, steel reduces the effect of galvanic corrosion when placed in contact with magnesium. Galvanic corrosion is common in assemblies where brass and magnesium are in direct contact due to the electric field generated by the coil packs.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국