Plastic Filter Pump Assembly

Application:

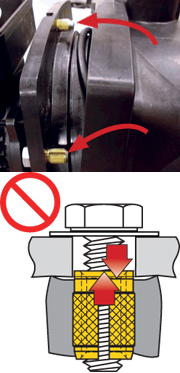

A pump and valve manufacturer contacted SPIROL to help solve an issue with their filter pump. The filter pump consisted of a cover fixed to the pump housing. With internal pressure and applied torque, the assembly needed to resist 22 N-m. They were using six Expansion Inserts with M8 bolts within 30% glass filled polypropylene plastic. A sub-contractor was manually installing each Insert at the perimeter of the housing flange. When required pressure was applied, the Inserts were coming off with the bolts resulting in the pump opening up. The client was looking for a reliable and efficient solution to meet his specifications.

SPIROL Solution:

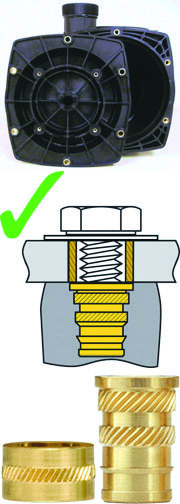

After review of the application, SPIROL Engineering determined that the diameters of the cover’s holes were bigger than the diameter of the Inserts; thus creating a jack-out condition. It was recommended that the customer use SPIROL’s Series 20 Headed Heat Installed Inserts combined with CL800 Compression Limiters. This style of Insert offers the greatest ease of alignment and installation with the added benefit of a head for increased bearing surface to prevent jack-out. It also has higher torque and pull-out values than Expansion Inserts. The Compression Limiters offer added bearing surface to avoid jack-out and prevent plastic creep during assembly life.

SPIROL also suggested that the customer use a semi-automatic HP Model Heat Installation Machine to install the Inserts.

This solution provided a high quality product and an efficient assembly process while exceeding the application’s performance requirements.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España