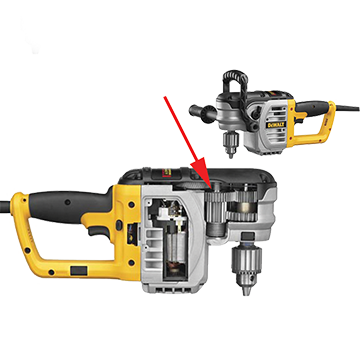

Heavy Duty Right Angle Drill

DEWALT, a subsidiary of Stanley Black and Decker, is a brand with a reputation for providing high quality professional power tools, contractor tools and accessories. DEWALT’s lead design engineer for drills was tasked with designing a high power right angle drill that is lightweight, compact, and portable. As is common with hand power tools, the goal with the design was to maximize performance while minimizing the size of the tool.

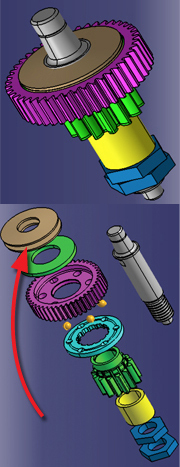

The design would incorporate a mechanical clutch built to limit maximum torque output to 70 ft-lbs. Absent the clutch, with the huge gear reduction of 75:1, the drill would be capable of producing a lock rotor torque at the spindle of 175 ft-lbs, transmitted directly to the operator of the tool. It was determined early on that the clutching thrust required in the space available could only be achieved by a Disc Spring design. Compared to conventional coil springs, Disc Springs offer a higher load capacity in less space. Additionally, longevity and reliability is a high measure of quality for professional tools used on a daily basis. The life and performance warranty of the tool was reliant on the Disc Spring design.

Early on in development, DEWALT’s engineers were working with a low cost Disc Spring supplier. DEWALT had developed and theoretically calculated the initial Disc Spring design. The first prototype built failed, with the new design achieving less than half the targeted cycle life. Analysis indicated premature fatigue failure of the Disc Spring was due to higher than expected stress, lesser quality material, and a less than ideal manufacturing process by the original supplier.

Determined to find a solution, the lead engineer on the project contacted SPIROL to discuss the Disc Spring design. SPIROL’s Application Engineering team evaluated the design objectives/constraints and quickly determined they could not be met by a standard Disc Spring. SPIROL essentially became an extension to DEWALT’s team and focused specifically on the Disc Spring portion of the design. SPIROL recommended a custom Disc Spring design that had alternate dimensions, material, and secondary operations. For this demanding and high performance application, these special features added significant value and ended up costing only pennies more compared to the product offered by the original supplier.

DEWALT tested SPIROL’s recommended Disc Spring and the tool far exceeded the cycle life requirement. By partnering together, DEWALT and SPIROL determined the best Disc Spring design for the new angle drill, minimizing costly development time for both companies.

DEWALT product images used with permission by DEWALT Industrial Tool Co.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국