Turret Punch Press Assembly

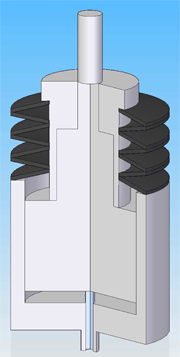

Traditional turret punch press tool designs utilize coil springs (die springs) to facilitate the stripping mechanism of a die. Rather than using a ram to push the punch through the sheet metal and pull it out, the spring automatically retracts the punch. This allows the ram to only have to work in one direction. The result reduces wear and extends the cycle life of the press.

Since the development of coil springs in turret tooling, engineers have been challenged to increase the productivity of turret presses even further. In a traditional press, the option of material type and material thickness is limited by the coil springs inability to produce a high force in a short linear distance. When this performance is necessary, coil springs will have a negative effect on the quality of the formed product and efficiency of the manufacturing process.

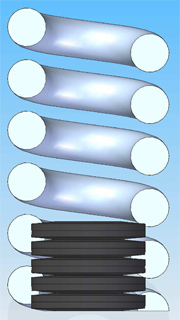

SPIROL® Disc Springs are the solution to form thick materials, large extrusions, and more complex designs. When stacked in series (Figure 1), they are capable of providing a greater, more consistent stripping force than coil springs and require less space. They have become an instrumental component in the advancement of turret punch press tooling

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

LOCATIONS

LOCATIONS USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España  한국

한국