Clutch Plate for Heavy Equipment

Alignment of components is critical in various powertrain and hydraulic systems. Traditionally Solid OD Ground Dowels have been used to provide the necessary alignment. However, these Ground Dowels require precision machined holes to ensure adequate interference between the Dowel and hole for retention and to keep the insertion force within a practical limit. Precision honing the holes, as compared to simply drilling the holes, results in substantially higher manufacturing costs.

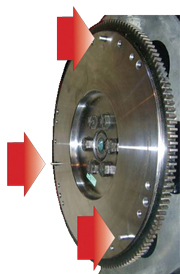

In a large 36” diameter clutch plate there were (24) holes containing a series of (12) ø16mm Solid Ground Dowels and (12) ø10mm size bolts in an alternating pattern around the OD of the plate.

In an effort to offer cost reductions while maintaining the required alignment, SPIROL recommended that the customer eliminate the (12) precision machined holes that were previously used for the Solid OD Ground Dowels. The remaining (12) holes were simply drilled to the recommended hole size for SPIROL’s standard ø10mm DB100 Dowel Bushing.

The OD of the Dowel Bushing compresses as it is installed into a hole. The spring action of the bushing’s material provides the radial force that keeps it in the hole once installed.

The Dowel Bushing has a hollow ID which allows the bolt to pass through the inside of the bushing after it has been installed thus eliminating the need for separate holes for the Alignment Dowels and bolts. In addition to eliminating (12) of the holes in the assembly, the ability of the Dowel Bushing to conform to a wider tolerance enabled the holes to be opened up from a total manufacturing tolerance of ø0.013mm to ø0.13mm — 10 times wider than the previous tolerance.

Even though the Dowel Bushing is flexible, it has enough rigidity to maintain the required alignment for the assembly. The overall positioning of the clutch plate using the Dowel Bushings performed in the exact same manner as it did with the Solid Ground Dowels which was proven through testing of over 60,000 cycles.

The customer predicted that they saved over $0.21 per dowel, and an additional $0.15 per hole. In total — the customer saved over $4.32 per clutch plate.

Similar solutions have been provided in hydraulic pump applications.

SPIROL has many alternative solutions for alignment applications which include different types of Dowels and Pins that offer the lowest unit and hole preparation costs.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España