The Difference Between Disc Springs and Belleville Washers

By

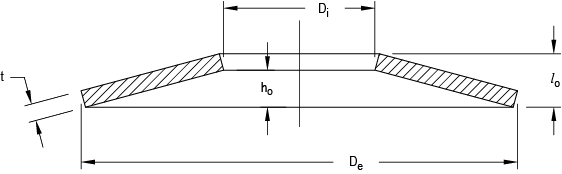

Download this WhitepaperDisc Springs and Belleville Washers are both conically shaped spring washers typically made from spring steels and designed to be loaded axially. Both can provide a higher degree of force in a relatively compact area as compared to coil springs or wave springs. While the terms “Disc Springs” and “Belleville Washers” are often used interchangeably, there are some technical, design, and application differences between the two products:

|

TECHNICAL DISTINCTIONS BETWEEN DISC SPRINGS AND BELLEVILLE WASHERS |

||

|

|

Disc Springs |

Belleville Washers |

|

Typical Applications |

Preloading, dynamic loading / cycling, predictable fatigue life important |

Static Applications |

|

Typical Materials |

High carbon steel < 1.25mm, |

High carbon steel |

|

Thickness |

0.2mm – 14mm |

Tend to be thicker for a given OD |

|

Standard Units |

Metric |

Imperial / Metric |

|

Force Requirements |

Force / deflection curves specified |

Static force / torque can be specified or no force specification |

|

Governed by International Standards |

DIN EN 16983 & 16984 |

DIN 6796 |

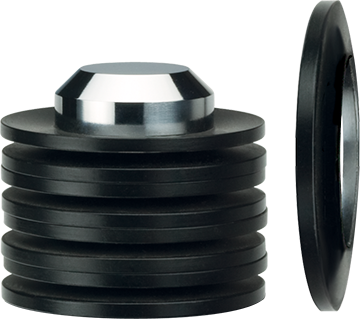

Belleville Washers are primarily used in heavy duty applications fastened together with a bolt where the load is considered static. Disc Springs can be statically loaded either continuously or intermittently, or dynamically subjected to continuous load cycling. Unlike Belleville Washers, Disc Springs are designed specifically to provide a repeatable force-travel relationship, and have a long and predictable fatigue life in dynamic or cycling applications. Disc Springs are commonly found in a variety of applications including pressure controls and regulators, vehicle braking systems, valves, shock absorbers, clutches, friction assemblies, and joints where thermal / weight cycling occurs. Disc Springs can be used as a single piece, or combined together into different configurations in stacks to achieve the desired force-deflection performance.

A defined list of standard Disc Spring sizes and associated load and deflection characteristics is available in DIN EN 16983 (formerly DIN 2093).

Selecting the most appropriate Disc Spring or Disc Stack configuration can be challenging. It is recommended that designers partner with experts in Disc Spring Application Engineering to determine the optimum Disc Spring for a particular application.

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España