Fuel Rail

Application:

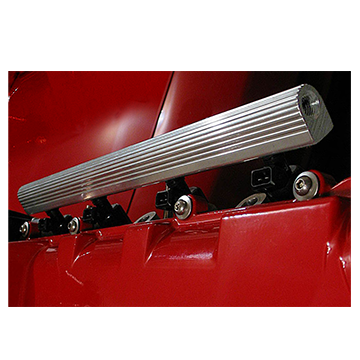

A fuel injection systems manufacturer had incorporated the use of two steel brackets to clamp the fuel rail to the top of the engine. The customer was looking at changing these brackets to plastic as a cost reduction. In order to prevent deformation of the plastic bracket during the tightening of the bolt, a Compression Limiter was required.

The customer originally investigated the use of a machined Compression Limiter, but the savings from changing the metal bracket to plastic would have been lost considering the high price of the machined Limiter. The customer approached SPIROL to help provide a lower cost solution for the Compression Limiter.

SPIROL Solution:

SPIROL Engineering recommended the use of a standard CL200 (non heat treated) Compression Limiter based on the rated proof load of the bolt that was used in the assembly. This roll-formed Compression Limiters is a fraction of the cost of a machined Compression Limiter. In addition, the flexibility of the roll formed Limiter enabled the customer to widen their hole tolerances which further reduced the cost of the assembly as the machined Limiter would required significantly tighter tolerances.

SPIROL’s objective is to recommend the lowest installed cost component. Due to the fact that SPIROL has a vast standard range of products, often times samples are provided from stock at minimal cost.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España