Toilet Fill Valve / Float Arm

An alternate solution to a brass rivet was required that would reduce piece price, increase efficiency, and eliminate potential quality issues associated with riveting.

PRIOR SOLUTION:

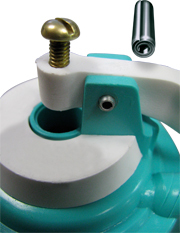

A plastic toilet fill valve was designed with a brass rivet to function as a link pin/axle upon which the float arm would rotate. The brass rivet was expensive and added a secondary operation which decreased manufacturing efficiency. As riveting relies upon impact to form the head it also introduced the potential for variation in ‘fit’ as well as scrap due to impact/over-compression. An alternate solution was required that would reduce piece price, increase efficiency, and eliminate potential quality issues associated with riveting.

The fill valve assembly consisted of a valve cap and link arm. A free fit was required as movement of the float could not be restricted without impairing valve function. The Coiled Spring Pin is an ideal low cost solution in applications of this kind. Coiled Spring Pins are designed with a pre-installed diameter larger than the recommended hole. The pin is compressed within the hole during installation and the resultant tension provides retention. By retaining the pin in the outer ears or valve cap and maintaining a clearance hole in the inner float arm link, a free fit relationship was established. The symmetrical Coiled Spring Pin could be easily fed and oriented for automated installation. This would eliminate the secondary riveting operation and provide the desired increase in efficiency.

SPIROL SOLUTION:

SPIROL Engineering recommended a light duty Coiled Spring Pin for use in this application. Light duty pins are an excellent choice for use in plastics as they provide superior flexibility while maintaining a strong joint. This eases installation and protects hole integrity to maintain long term fit & function. As the pin would be located in a moist environment it was provided in 300 series austenitic stainless steel to maximize corrosion resistance and reduce cost. Coiled Spring Pins are a symmetrical solution that can easily be fed, oriented, and installed and SPIROL Automation can provide cost effective equipment to facilitate this process. This solution satisfied the customer’s cost requirements, increased their efficiency, and reduced risk to their overall product quality.

Complimentary Applications Engineering Support: SPIROL Engineers will review your application needs and work with your design team to recommend the best solution.

Additional Resources

Why Should You Partner with SPIROL?

Our core purpose is to be a resource that facilitates the reduction of your assembly costs, improves your product quality and enhances your overall competitiveness. In addition, SPIROL offers:

CHINA

CHINA Malaysia

Malaysia  한국

한국  USA

USA  Canada

Canada  United Kingdom

United Kingdom  Deutschland

Deutschland  México

México  Brasil

Brasil  Česká republika

Česká republika  France

France  España

España